- Products

- Overview

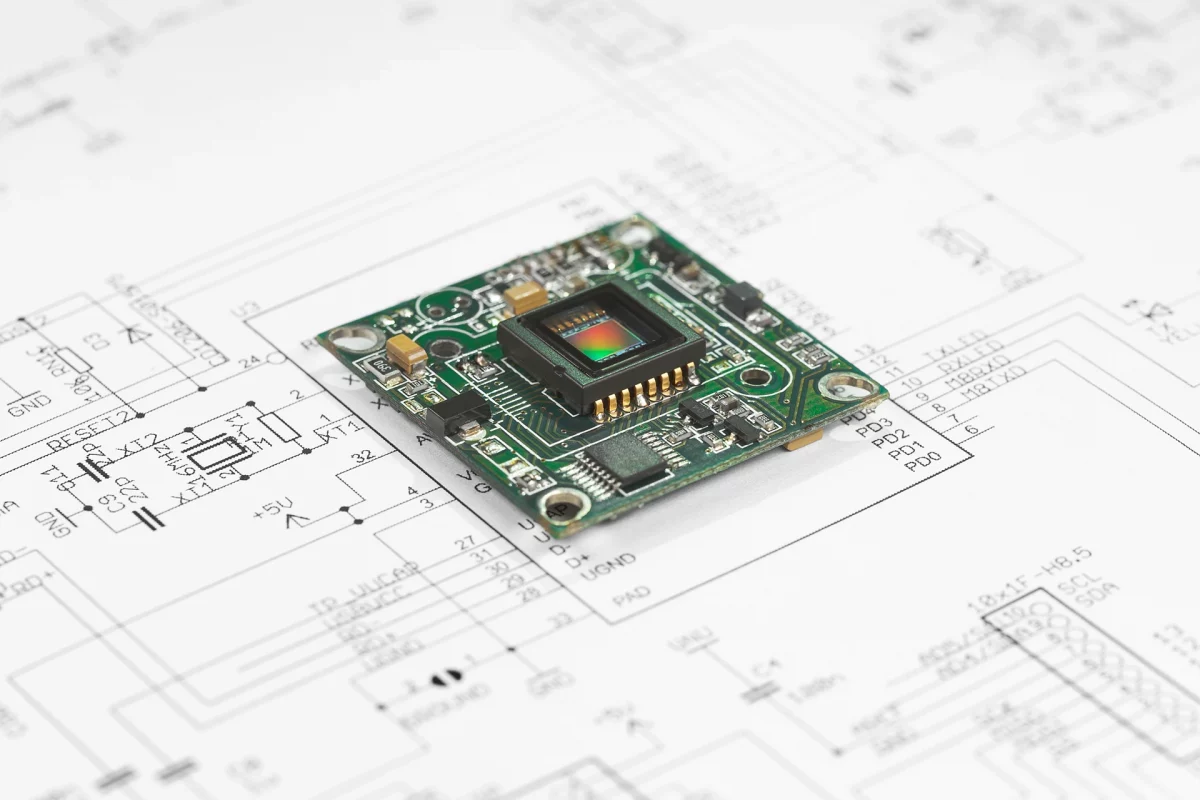

- Batch soldering systemsBatch soldering systems Batch soldering systems are ideal for precise, reproducible and gentle soldering of electronic assemblies using the vapor phase process. Thanks to standardized production profiles, the systems enable a consistently high-quality soldering process that can be implemented easily and reliably. The flexible, reliable and user-friendly batch soldering systems offer decisive advantages, particularly in small series production, prototyping, laboratory applications and rework processes. For example, the energy-efficient IBL batch vapor phase soldering systems do not require complex programming. These compact soldering systems use condensing vapor in the fully automatic soldering process for uniform heat transfer in an oxygen-free soldering atmosphere. This prevents the assembly from overheating, significantly reduces material stress and minimizes void formation. Thanks to their properties, these systems are particularly suitable for small series production as small series soldering systems.

- Inline soldering systemsInline systems Inline vapour phase soldering systems are fully automatic soldering systems for line production that have been specially developed for the reliable and cycle time-optimized series production of electronic assemblies. Inline soldering systems integrate vapor phase soldering seamlessly into the production line and thus enable continuous and reliable inline soldering of assemblies. Thanks to standardized interfaces and predefined soldering programs, the processes can be flexibly adapted to different soldering requirements. Our automated inline soldering systems therefore ensure maximum precision and efficiency in the line. These systems offer additional advantages, particularly in the area of inline vacuum soldering, such as void-free soldering even for complex and sensitive assemblies. IBL's inline soldering systems guarantee maximum process reliability, repeat accuracy and efficiency and are ideal for the industrial production of medium to large quantities. Our systems are high-performance production solutions for electronics that are designed for quality and future-proofing.

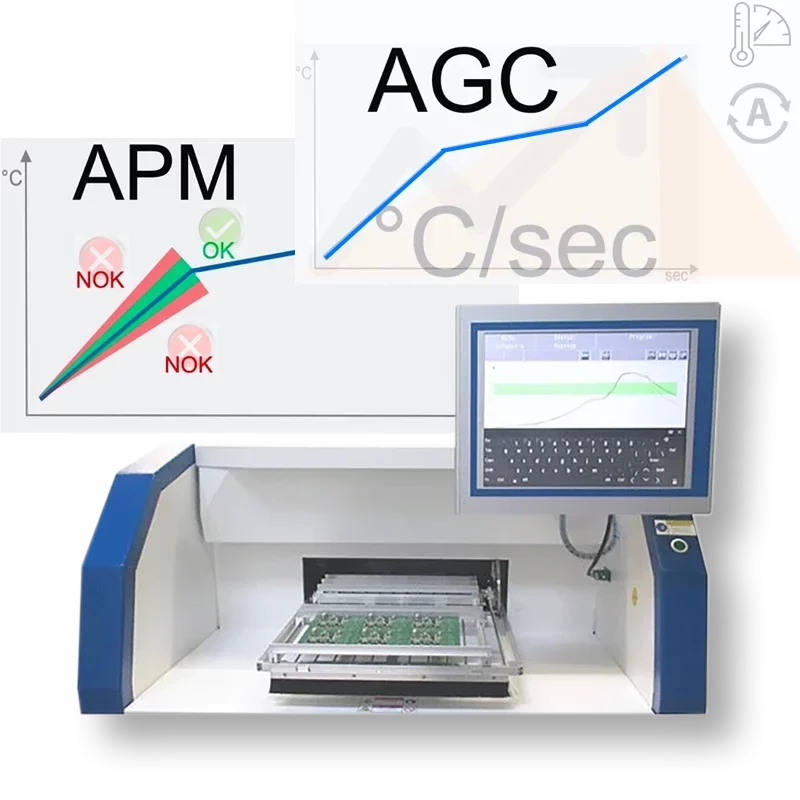

- Vacuum soldering systemsHighest soldering quality thanks to vacuum systems The latest generation of vapor phase soldering systems with integrated vacuum function reliably prevents void formation during the soldering process. These advanced vacuum soldering systems are particularly suitable for void-free vacuum soldering of demanding components such as BGAs or multilayer PCBs with a high component mix and guarantee consistently high soldering quality. Vacuum soldering for BGAs and complex assemblies in particular is significantly improved by the precise process control. The integrated Intelligent Profiling System of the vacuum soldering systems allows precise control of the temperature rise in order to achieve optimum, application-specific vacuum soldering processes. In combination with the patented Soft Vapour Phase, excessive heating of the components is reliably avoided. Thanks to the excellent heat transfer in an inert, oxygen-free atmosphere, efficient vacuum brazing is guaranteed. The use of additional shielding gases such as nitrogen is not necessary. In addition to its technical performance, the inline brazing system also impresses with its low energy consumption and low operating costs, making it the ideal solution for automated vacuum brazing in modern production environments.

- Special machinesSpecial solutions for complex requirements We also design customized special machines for soldering complex and demanding assemblies with specific dimensions and weights: Oversized (over 1000 mm) With excess height (over 100 mm) For heavy assemblies (over 10 kg) Your challenge is our task As an experienced partner in mechanical engineering in soldering technology, we develop systems for electronics production that are precisely tailored to your requirements. In addition, we provide you with competent support for Questions about special process control the integration of automated soldering processes comprehensive process documentation With our innovative vapor phase soldering systems, we offer you tailor-made solutions in soldering technology. We are also happy to take on your challenge!

- GaldenEfficient heat transfer through condensation Galden is heated in the soldering system until it vaporizes and produces a homogeneous vapour. This vapor condenses on the cooler surfaces of the electronic assembly and transfers the heat very efficiently. Special advantage As the vapor temperature is limited by the boiling point, overheating of sensitive components is effectively prevented - a key advantage in temperature-sensitive soldering: temperature-sensitive soldering lead-free soldering with higher temperature requirements Closed circuit - safe and sustainable The condensed Galden vapor flows back into the liquid container and is vaporized again. This results in a closed circuit. Due to its chemical inertness, non-flammability and reusability, Galden is particularly suitable for industrial soldering processes. Galden also ensures uniform, gentle and reproducible heat transfer. IBL recommends the heat transfer agent Galden from SYENSQO for use in vapor phase soldering systems. The LS and HS series were developed in collaboration with SYENSQO to meet the requirements of vapor phase soldering: maximum thermal stability consistent quality even over long periods of use Galden is characterized by the following added values: High thermal stability - ideal for controlled heat transfer Chemical inertness - does not react with other substances Low viscosity - enables efficient heat transfer Non-flammable & non-toxic - safe for industrial use Defined boiling points - for precise temperature control during soldering

- Accessories

- Processes

- The company

- Service

- Career

- Latest news