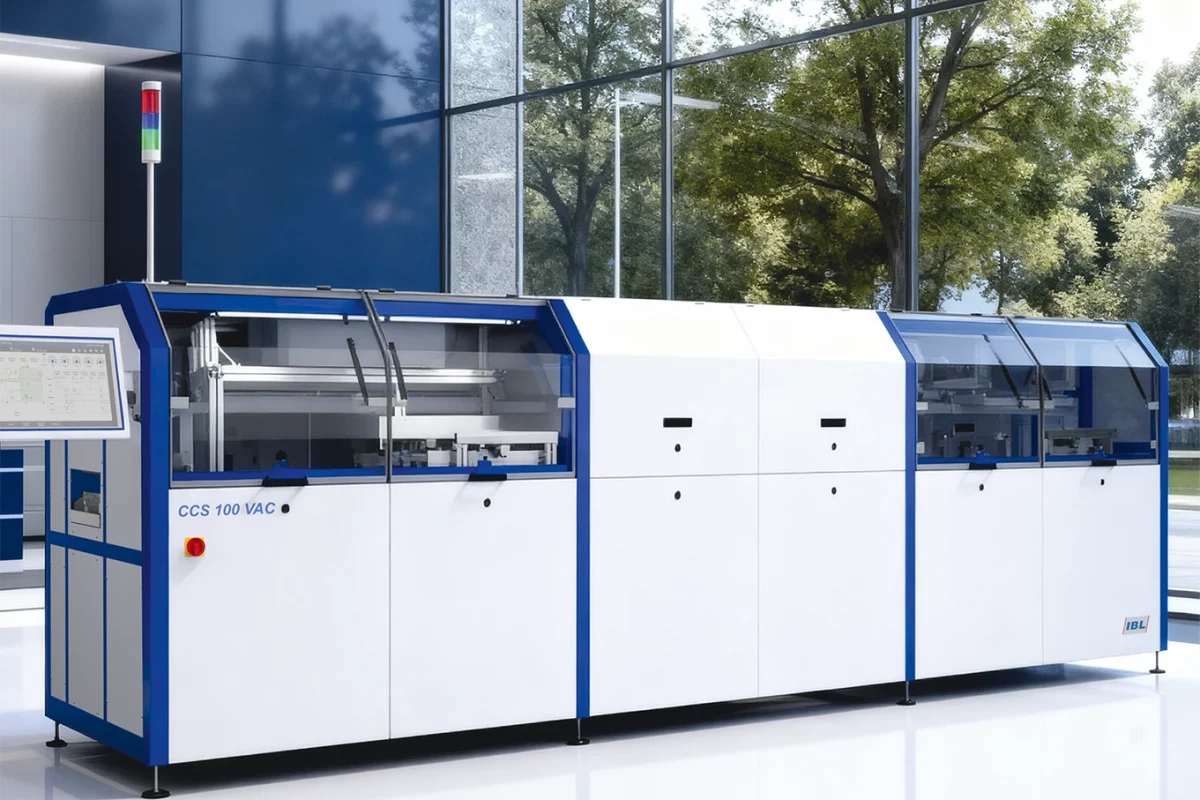

Vapour phase soldering, also known as vapour phase soldering (VPS) or condensation soldering, is a particularly gentle and precise soldering process in electronics production. It uses the physical properties of a vapourous heat transfer medium, usually a special, thermally stable perfluoropolyether fluid such as Galden, to evenly heat assembled circuit boards. The medium is heated in a closed system up to its defined boiling point, which is typically between 200 °C and 260 °C. In this state, a dense vapour is formed. In this state, a dense vapour is created into which the assembly is inserted. When the hot vapour hits the cooler surfaces of the assembly, it condenses and releases a considerable amount of latent heat. This condensation heat ensures extremely uniform and controlled heating of all components, regardless of their size, shape or thermal mass. As soon as the soldering temperature is reached, the reflow phase begins, in which the solder paste melts and the electrical connections are made.

A major advantage of this process is the automatic temperature limitation. As heat is transferred exclusively by condensation, the temperature of the assembly can never exceed the boiling point of the medium. This protects even the most sensitive components from overheating and enables a consistently high soldering quality.

After the soldering process, the assembly is removed from the vapour zone and cooled down in a targeted manner. These properties make vapour phase soldering particularly suitable for demanding applications in the aerospace, medical technology, automotive and defence industries and wherever maximum process reliability, reproducibility and material protection are required.