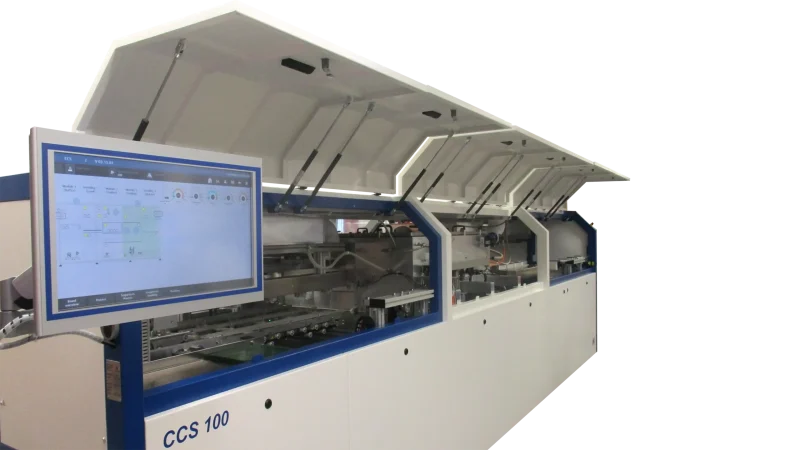

Modular and customizable for medium to large series

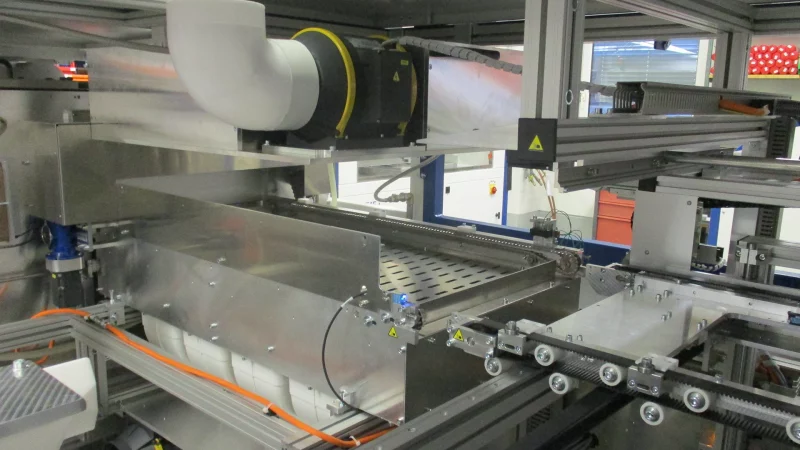

Vapour Energy Control (VEC) - patented process innovation

Furthermore, the newly developed, patented Vapour Energy Control (VEC) has set a new benchmark in the field of process technologies for vapour phase soldering systems.

The advantages:

- extremely responsive control of automated inline soldering

- full flexibility in profile design

- reproducible soldering without moving the assembly in the steam

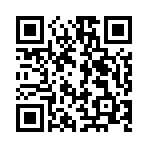

Modern control and complete data integration

The system control allows precise, repeatable soldering processes. Process values and steps can be viewed at any time.

Data management takes place via an integrated industrial PC, visualized via a 21.5″ HMI.

This technology enables:

- simple integration into existing networks

- comprehensive traceability functions

- seamless process data acquisition

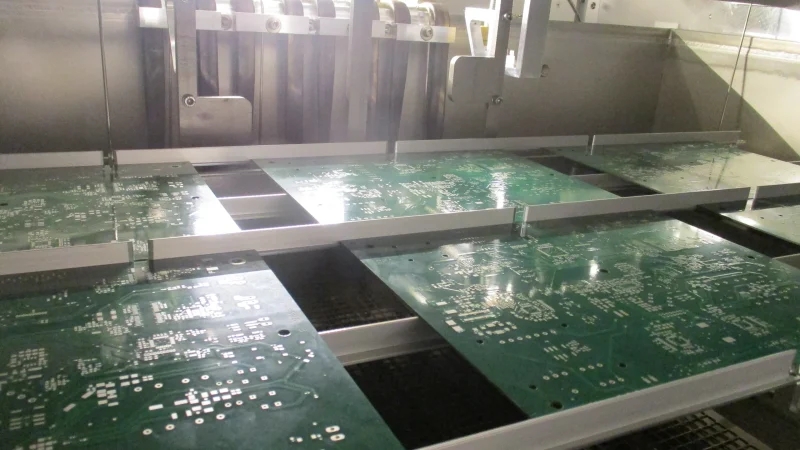

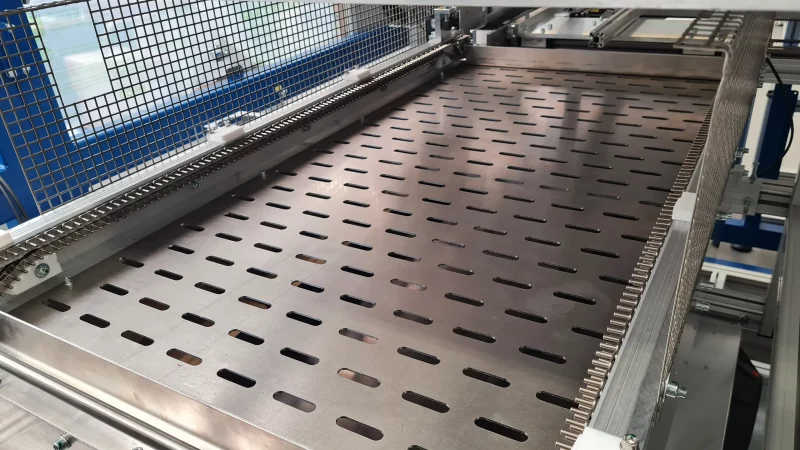

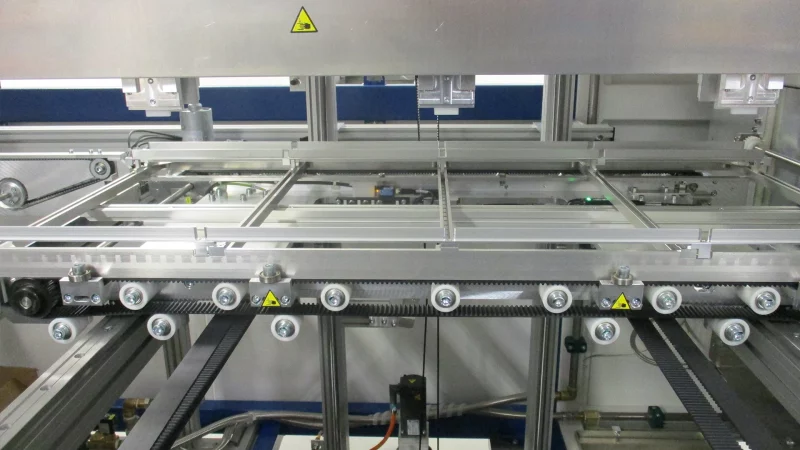

Workpiece carrier for cycle time-optimized inline soldering

The CCS100 is designed for cycle time-optimized inline production. Individual assemblies and workpiece carrier systems with several assemblies can be soldered within the system. A multiple carrier system with a variable track configuration of the workpiece carriers can be integrated. The workpiece carriers are adapted to the assemblies to be soldered on a product-specific basis. A workpiece carrier return conveyor and automatic width adjustment of the conveyor belts also enable work to be minimized.