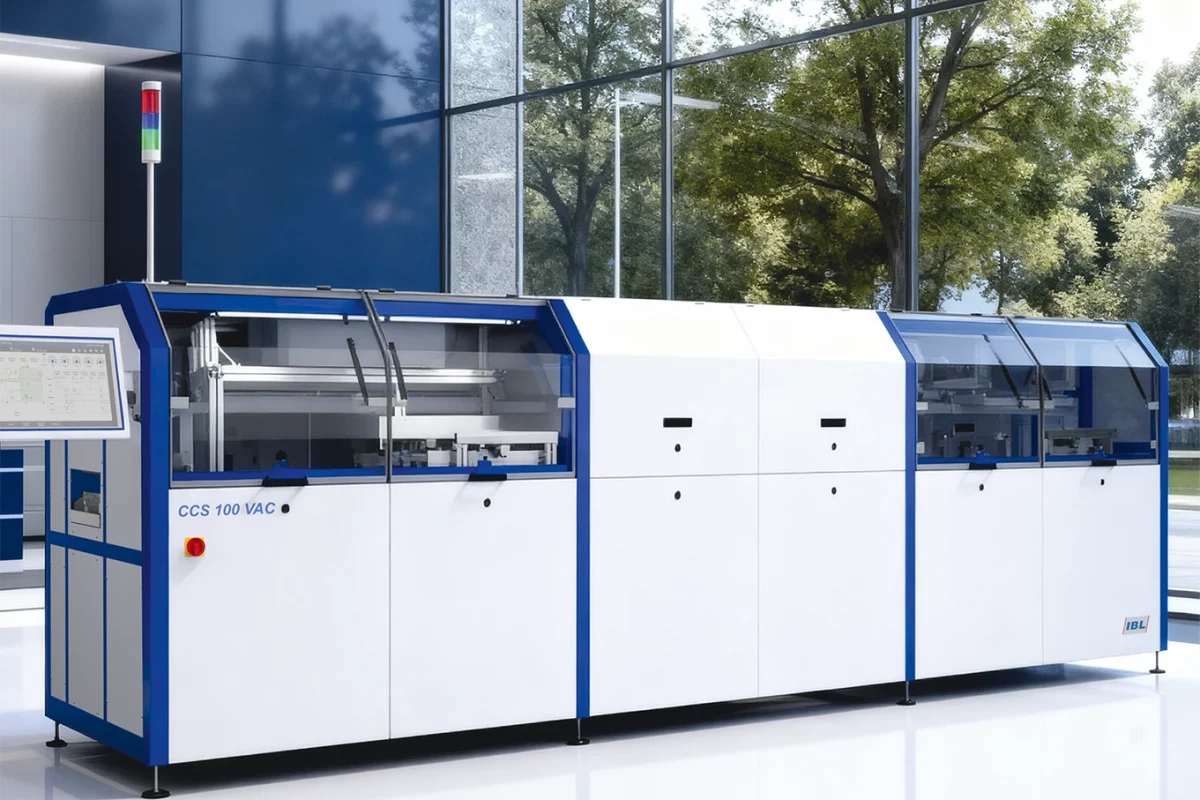

The BLC series was specially developed for precise and reliable soldering using the batch vapour phase process. These batch soldering systems enable an efficient, environmentally friendly and consistently reproducible soldering process with excellent heat transfer and minimal void formation.

With the IBL BLC 420, BLC 620 and BLC 820 batch soldering systems from BLC, even the most demanding soldering tasks in assembly production can be carried out effortlessly. Assemblies of different sizes, from simple to complex, can be processed simultaneously in these compact soldering systems without causing thermal overload or damage. This makes the systems ideal for small series production.

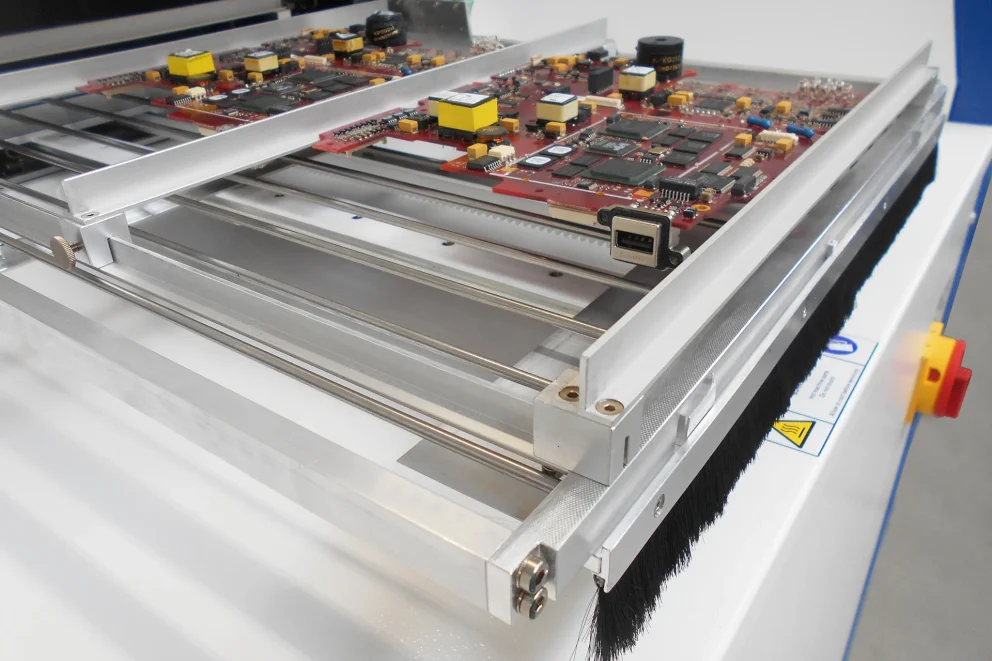

The compact BLC series is available in various machine types and supports carrier sizes from 450 × 540 × 80 mm to 850 × 540 × 80 mm. All Small series soldering systems can be fully integrated into existing production concepts.

The integrated Intelligent Profiling System (IPS) enables:

- precise control of the temperature curve and

- the creation of individual soldering profiles in just one step.

The patented Soft Vapour Phase technology reliably prevents sensitive components from overheating. This reduces material stress to a minimum. At the same time, the excellent heat transfer in an oxygen-free, inert environment ensures the highest soldering quality without the use of expensive nitrogen.

Thanks to the user-friendly two-chamber design with large touch display, the system is particularly easy to set up and operate.

- soldering can be carried out with identical soldering profiles regardless of the weight of the assemblies

- this ensures a consistent and reproducible production process