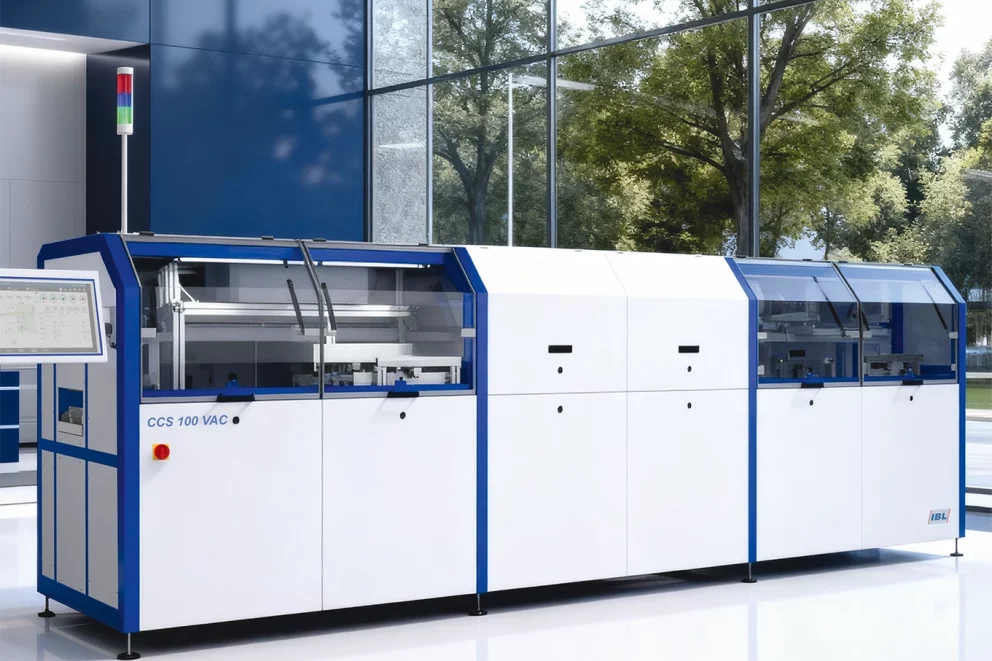

IBL Löttechnik GmbH will be exhibiting at the productronica 2025 their new vapour phase soldering system CCS100 VAC before. The new reflow soldering system is designed for inline production and is characterized by energy-efficient and cost-saving vacuum soldering. Thanks to very good heat transfer in an oxygen-free atmosphere, the system works without the need for additional nitrogen.

„The CCS100 series, which also includes the vacuum version, is characterized by high process flexibility in 24/7 operation and a modular system architecture.“

Olaf Cieply, Sales Manager at IBL GmbH

In modern electronics production, product variants, batch sizes and assembly geometries change frequently. The CCS100 VAC takes this trend into account. Thanks to the flexible multi-carrier system and the variable width configuration, different PCB formats and track lengths can be processed in inline operation. This makes the system equally suitable for small and medium-sized series, pilot productions or high-speed line production. Thanks to its easy adaptability to new products, the system remains economically viable in the long term. Thanks to its unique system architecture, the CCS100 VAC is particularly suitable for vacuum soldering demanding components such as BGAs.

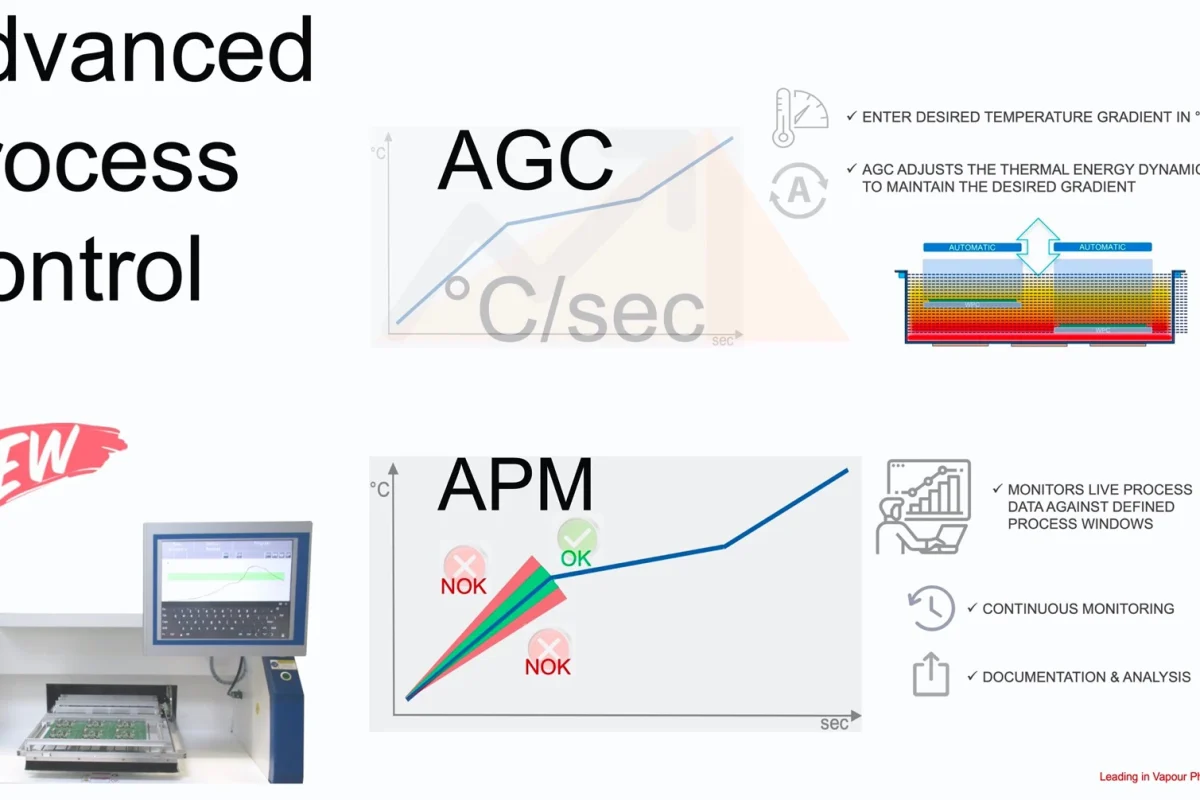

The strength of the CCS100 VAC lies in its precise temperature and process control. The homogeneous heat distribution in the soldering chamber ensures uniform soldering profiles, even for complex assemblies with a high component density. At the same time, the vacuum reduces the formation of air pockets and ensures uniform, low-void solder joints. All process data is recorded and can be documented for seamless traceability and quality assurance. Users benefit from reproducible results and maximum process reliability, regardless of the operator or batch size. An integrated, energy-efficient bottom cooling area ensures short process cycles and protects temperature-sensitive components after the soldering process. The compact design and the return of the workpiece carriers enable seamless integration into existing inline production concepts. This means that the CCS100 VAC can be integrated into automated production environments without major modifications and supports short cycle times, high capacity utilization and a continuous material flow.

Furthermore, the CCS100 VAC has a patented Vapour Energy Control (VEC), which enables high-precision control of the vapour phase soldering process. VEC monitors and controls the temperature profile, vapour output and energy supply in real time so that specified profiles can be reliably run and quickly adapted during process changes.

„This ensures optimum heat transfer, uniform solder joint quality and reproducible soldering results, even with demanding assemblies or a high cycle rate.“

Olaf Cieply

Equipped with a powerful industrial PC and large touch HMI, the CCS100 VAC offers comprehensive options for process monitoring, data analysis and network integration. The machine communicates with higher-level MES or ERP systems via common interfaces and provides process data in real time. This enables end-to-end traceability and provides valuable key figures for optimizing production. The CCS100 VAC is therefore ideally prepared for the requirements of modern smart factory environments. Thanks to its modular design, optimized accessibility of all assemblies and integrated automatic functions, the CCS100 VAC minimizes downtimes and considerably simplifies maintenance work. Automatic track width adjustment, intelligent material return and self-monitoring fluid and filter systems ensure that operator intervention is reduced to a minimum. The result is consistently high system availability, which makes a decisive contribution to overall system efficiency, especially in highly automated inline electronics production.

„The CCS100 VAC offers a lot of added value for electronics production in inline series production, as it combines the advantages of inline technology with flexible track runs, high availability and low maintenance, thus enabling high soldering quality and precise process control with minimized cycle times.“

Olaf Cieply

IBL will be presenting the CCS100 VAC at productronica 2025 in Hall A4, Stand 218.