Electromechanical components are indispensable in modern assemblies and at the same time particularly sensitive to thermal stress. Especially in vapour phase soldering, uncontrolled temperature curves can lead to stresses, material deformation or loss of function. In a current article on EPP Industrie shows how thermal stress in electromechanical components can be avoided in the long term. The focus is on precisely controlled heating and cooling processes that prevent overheating and minimize temperature gradients. In addition to optimizing the process parameters, in-line temperature measurement also plays a key role in identifying and reducing critical peaks at an early stage. Additional loads can be further reduced by using suitable materials and sophisticated component designs.

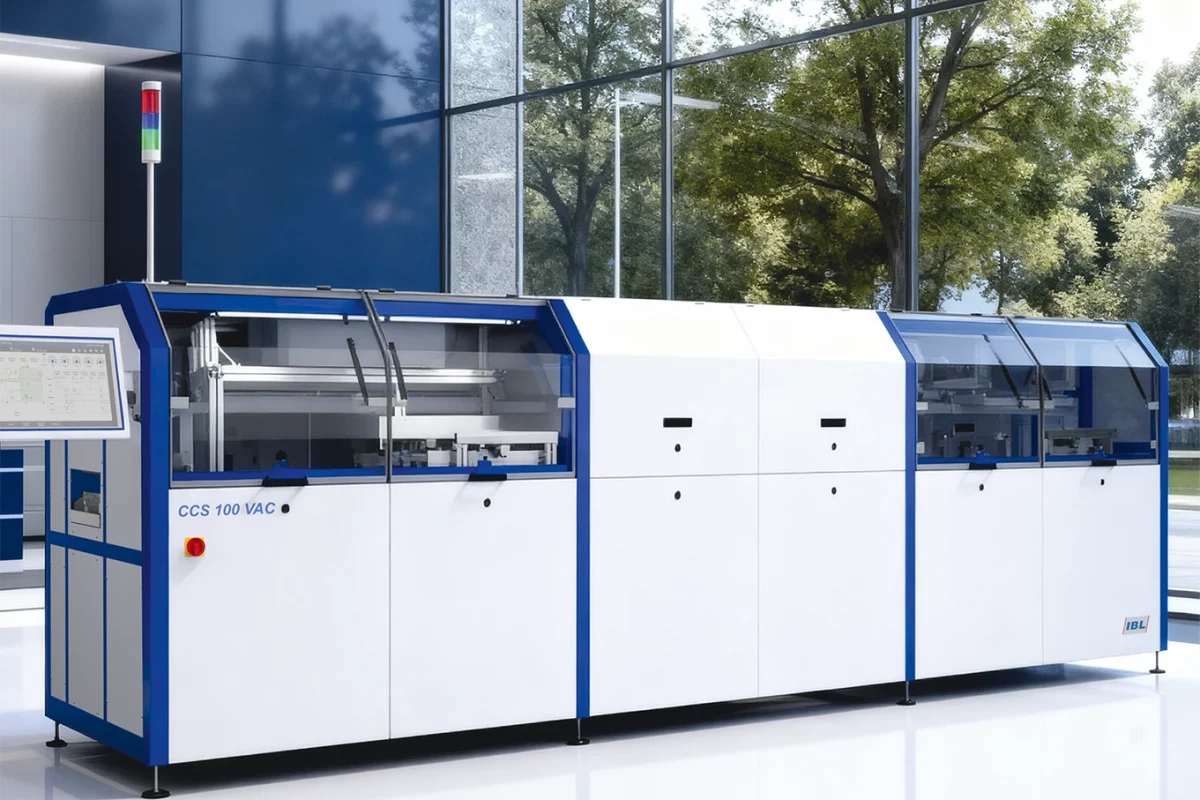

IBL-Löttechnik consistently adopts these approaches and develops soldering processes that ensure the functional reliability and service life of sensitive components. With our systems and our advice, we help customers to arm their production against thermal stress, reduce rejects and rework and permanently increase the quality of their products. This makes vapour phase soldering a reliable and economical process for even the most demanding electromechanical assemblies.