The best soldering method achieving gentle heating and optimum quality

All soldering processes have one thing in common: they are able to securely attach components onto specified base material. However, for greater process accuracy, higher quality solder joints, consistently repeatable heating, and lower reflow costs, vapor phase soldering (also known as condensation soldering or vapor phase reflow), is the most flexible, simplest and most reliable reflow soldering method. It is ideally suited for all types of SMT components and base materials. It allows processing of all components without elaborate setup and without temperature profiling.

Basic configuration

A chemically inert fluid is used for the heat transfer. This fluid is non-corrosive, electrically non-conductive and does not deteriorate over time. The boiling point is very accurate depending on the application, most fluids have boiling points between 165°C up to 260°C. Other temperatures are also available.

Process

As soon as the fluid starts to evaporate, a layer of saturated vapor and condensing fluid covers the soldering area creating an inert (oxygen-free) atmosphere. The vapor’s weight is greater than the surrounding air and forms a protective gas atmosphere (0 ppm oxygen) without the need for any additional gases, such as nitrogen. As soon as the solder material is immersed into the vapor zone, the vapor condenses on the solder material and transfers its heat. Irrespective of the time the solder material remains in the vapor, its temperature can never exceed the defined maximum vapor temperature.

As a result, the solder process can be reliably reproduced and offers ideal pre-conditions for a reliable and repeatable process control. The vapor phase soldering process achieves perfect results on a wide range of assemblies, from flexible to multi-layer substrates, reliably without overheating.

Minilab

Minilab  SV260 Economy

SV260 Economy  SV540 Economy

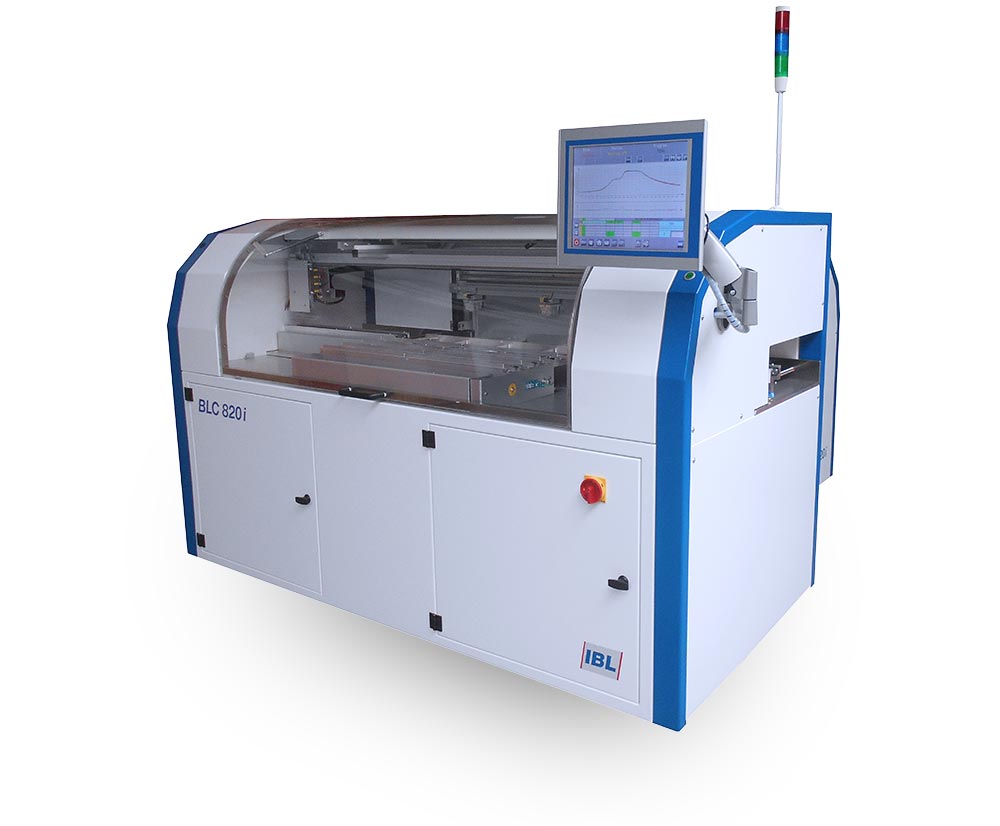

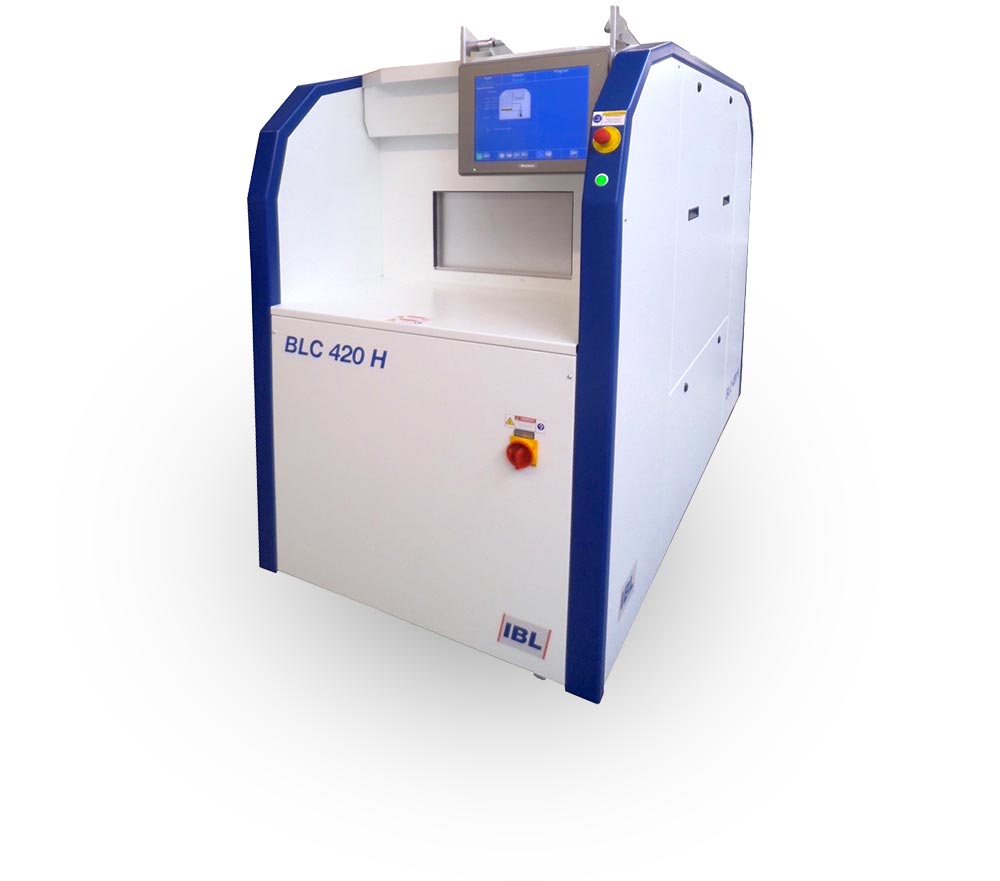

SV540 Economy  BLC-Serie

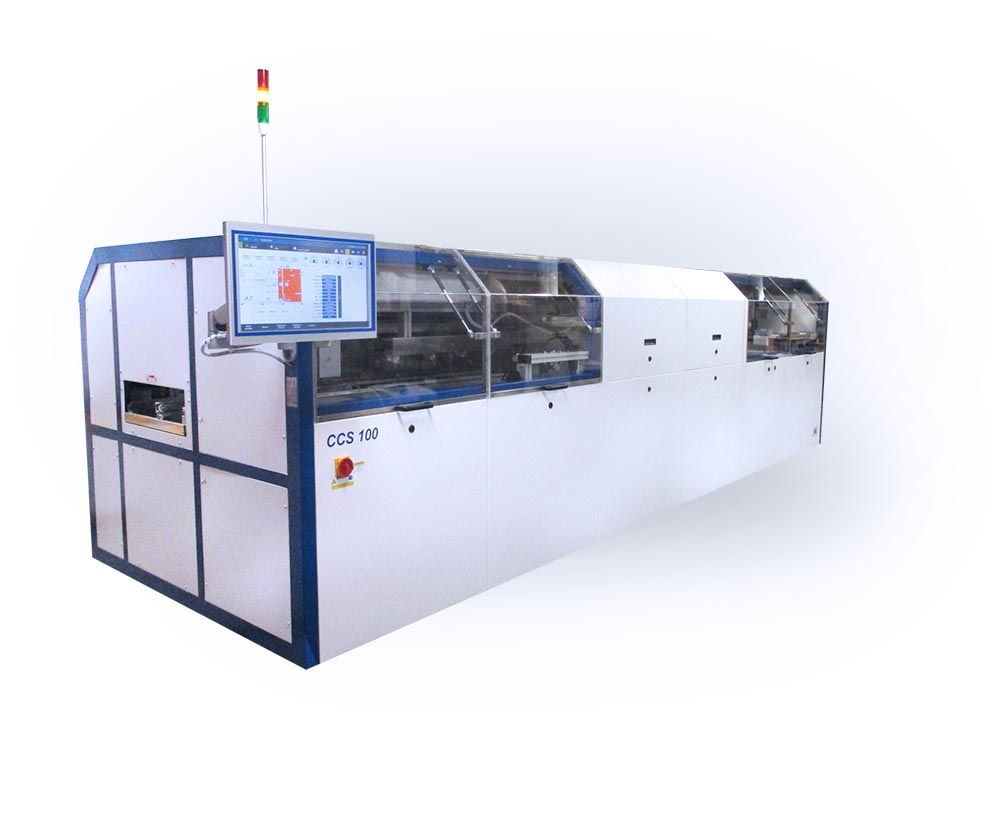

BLC-Serie  CCS100

CCS100  BLC Inline Anlagen

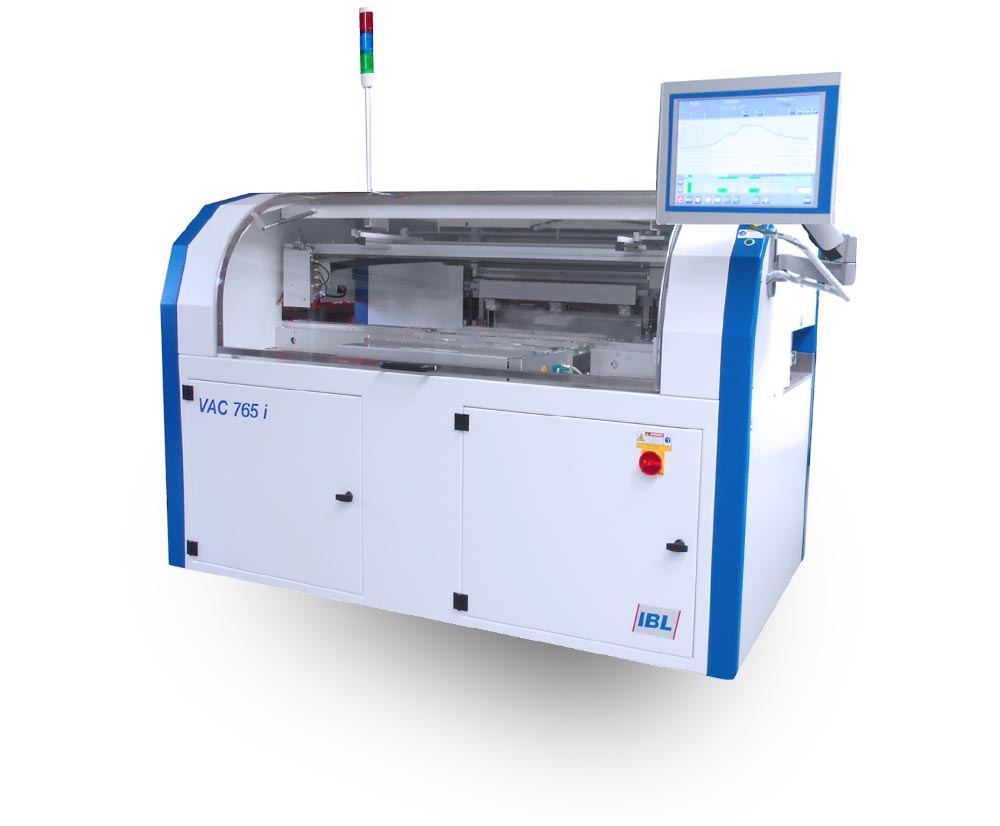

BLC Inline Anlagen  VAC Inline Anlagen

VAC Inline Anlagen  VAC745/765

VAC745/765  Customized Solutions

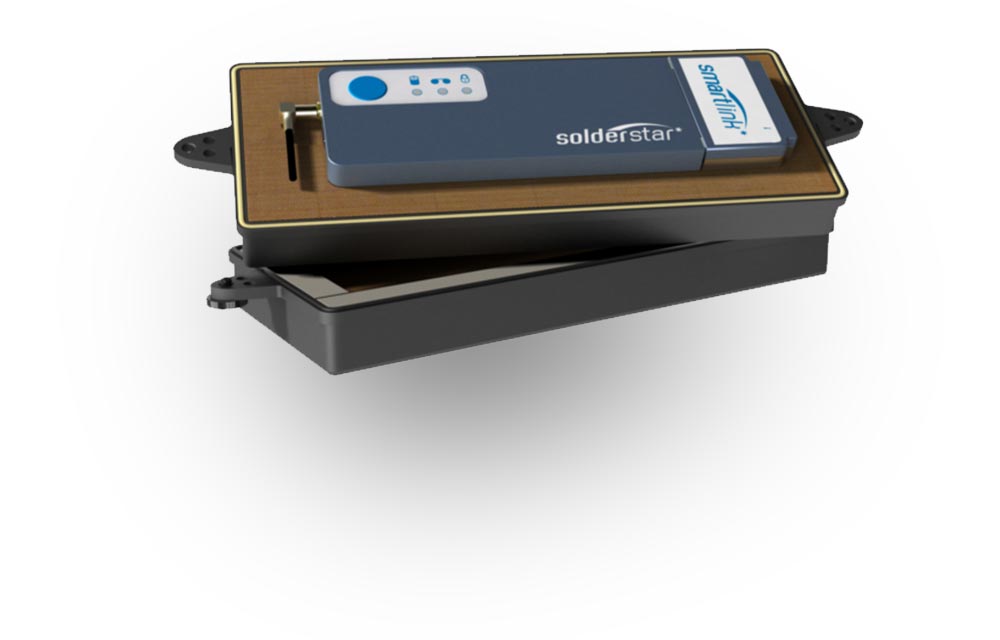

Customized Solutions  Temperature-Profiling

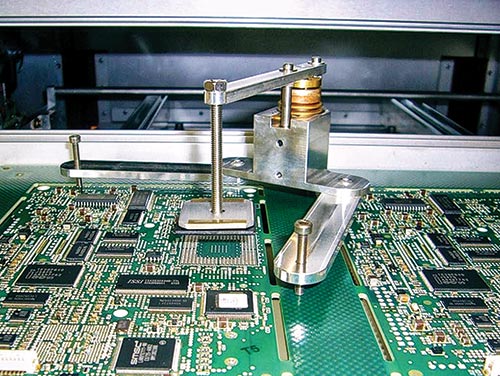

Temperature-Profiling  Rework

Rework  Fluid (Galden®)

Fluid (Galden®)