IBL has been a leader in the field of vapor-phase technology since 1987, due to the soldering experience and the innovative development work as a market and technology leader in the area of vapor phase soldering. Today IBL has a broad customer base from all sectors of the electronics industry and over 2000 installed machines worldwide, providing an unsurpassed support network. Highest soldering quality, low operating costs and customer-oriented solutions are the key words for IBL.

For the 30th anniversary the company presented its new vapor phase soldering systems of the series BLC and VAC. The machines with new design are available as batch or inline and in various sizes. Maximum soldering quality and flexibility are realized by countless patented functions. The PC-controlled systems in combination with the 15 “touch screen offer a simple operation with full network capability, unlimited program memory and permanent data recording. The Intelligent Profiling System (IPS) allows the creation of a solder profile in just one step, thanks to the pilot mode, and thus significantly shortens installation and changeover times. The vacuum unit combines the advantages of the vapor phase with the vacuum process and guarantees void-free solder joints with highest quality.

For the 30th anniversary the company presented its new vapor phase soldering systems of the series BLC and VAC. The machines with new design are available as batch or inline and in various sizes. Maximum soldering quality and flexibility are realized by countless patented functions. The PC-controlled systems in combination with the 15 “touch screen offer a simple operation with full network capability, unlimited program memory and permanent data recording. The Intelligent Profiling System (IPS) allows the creation of a solder profile in just one step, thanks to the pilot mode, and thus significantly shortens installation and changeover times. The vacuum unit combines the advantages of the vapor phase with the vacuum process and guarantees void-free solder joints with highest quality.

The soldering system operates in a completely inert atmosphere during the entire reflow and vacuum process. Integrated fan, energy management system, automatic medium filtration as well as media level control are just some of the many advantages of the machine. Furthermore, the vacuum system has a large selection of adjustable solder profiles and the operator has the option of soldering lead-free and leaded components with only one medium with different boiling points. The automatic monitoring of the vacuum pressure is also a great advantage of the newly designed system. For the near future we have planned some new developments which we can look forward to.

Minilab

Minilab  SV260 Economy

SV260 Economy  SV540 Economy

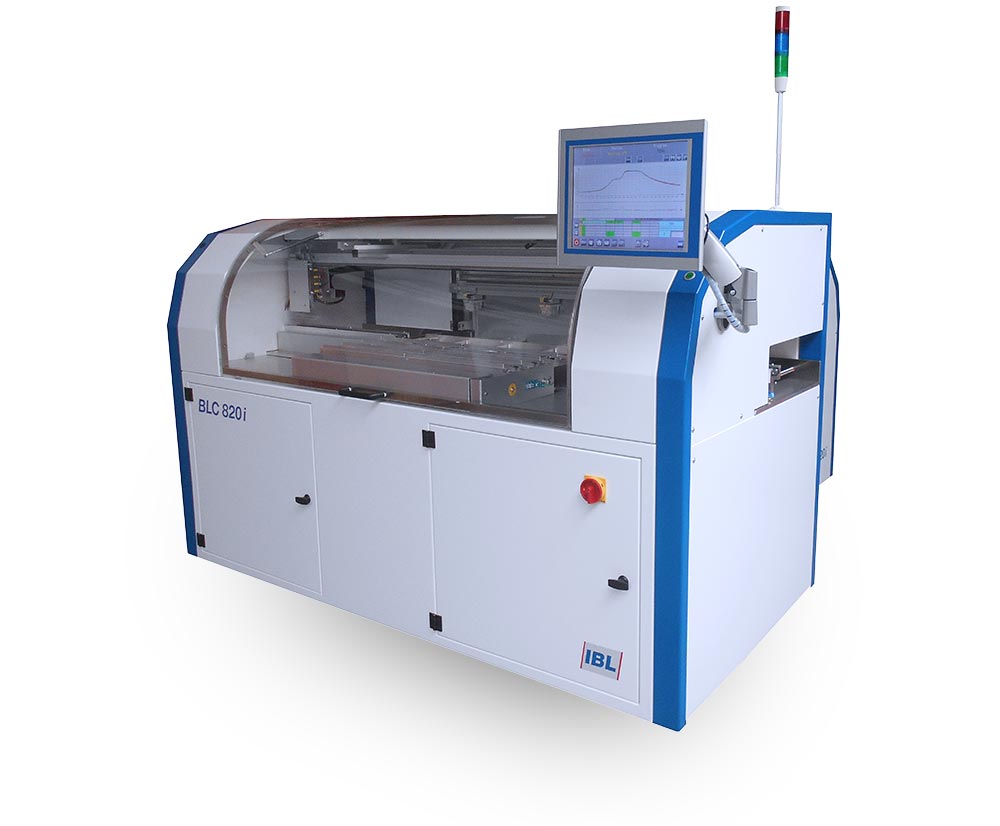

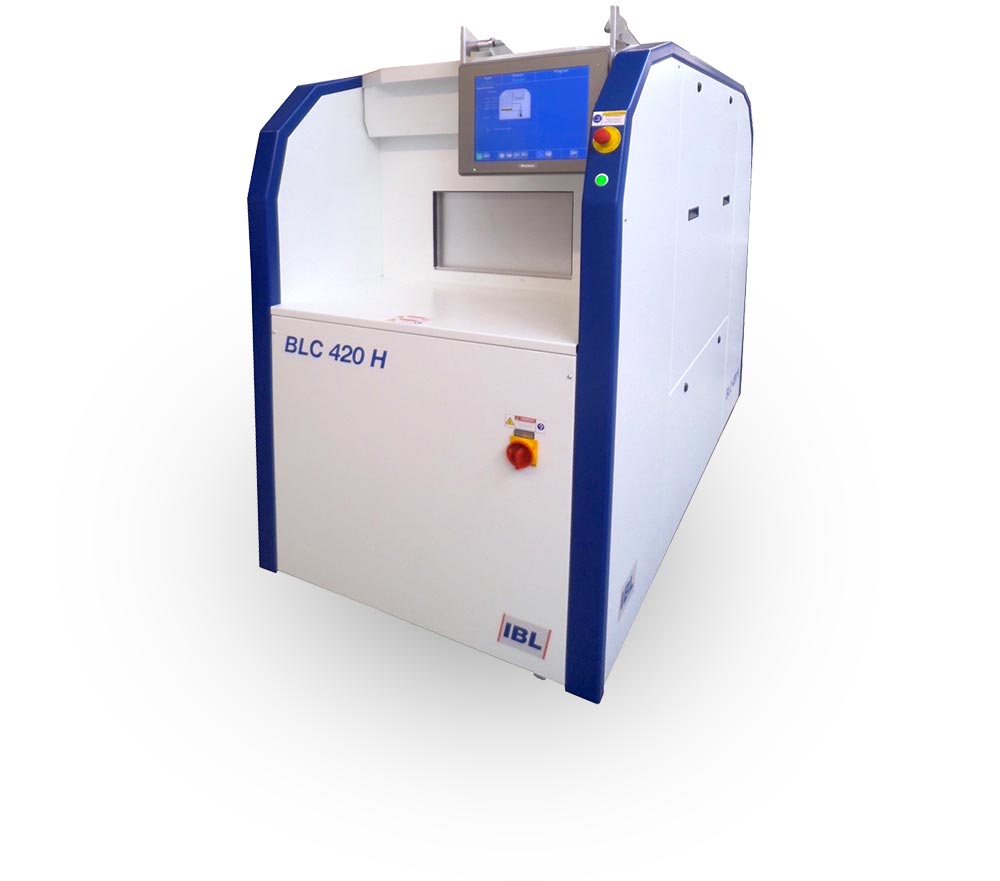

SV540 Economy  BLC-Serie

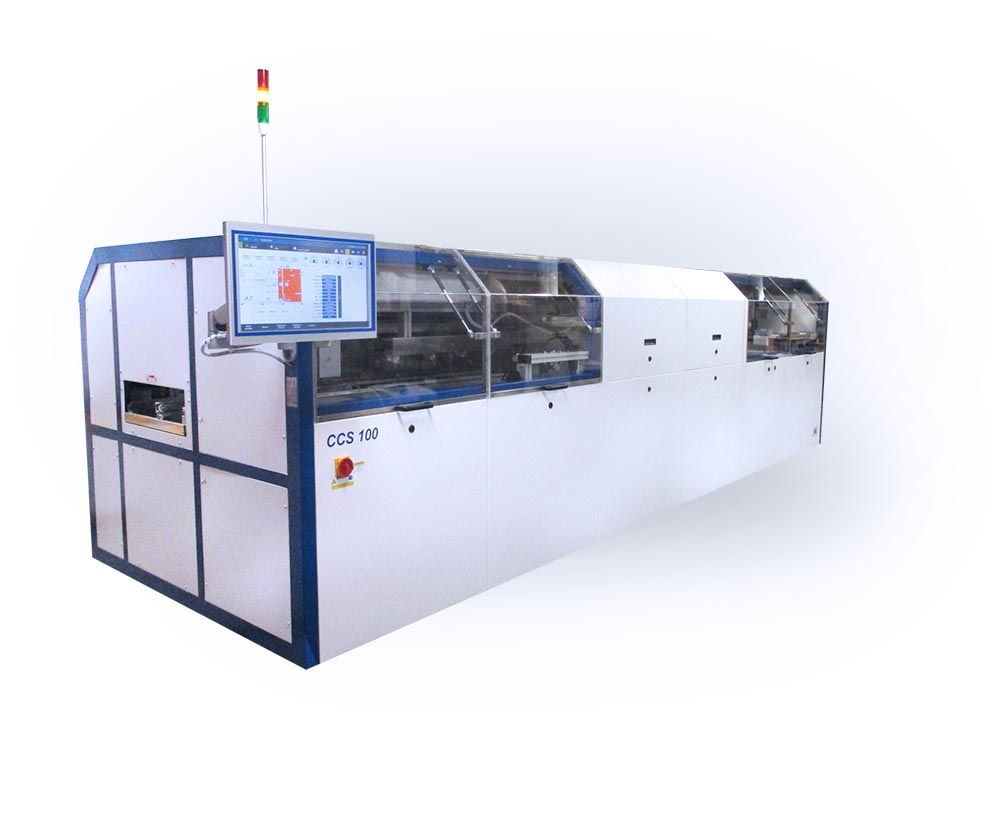

BLC-Serie  CCS100

CCS100  BLC Inline Anlagen

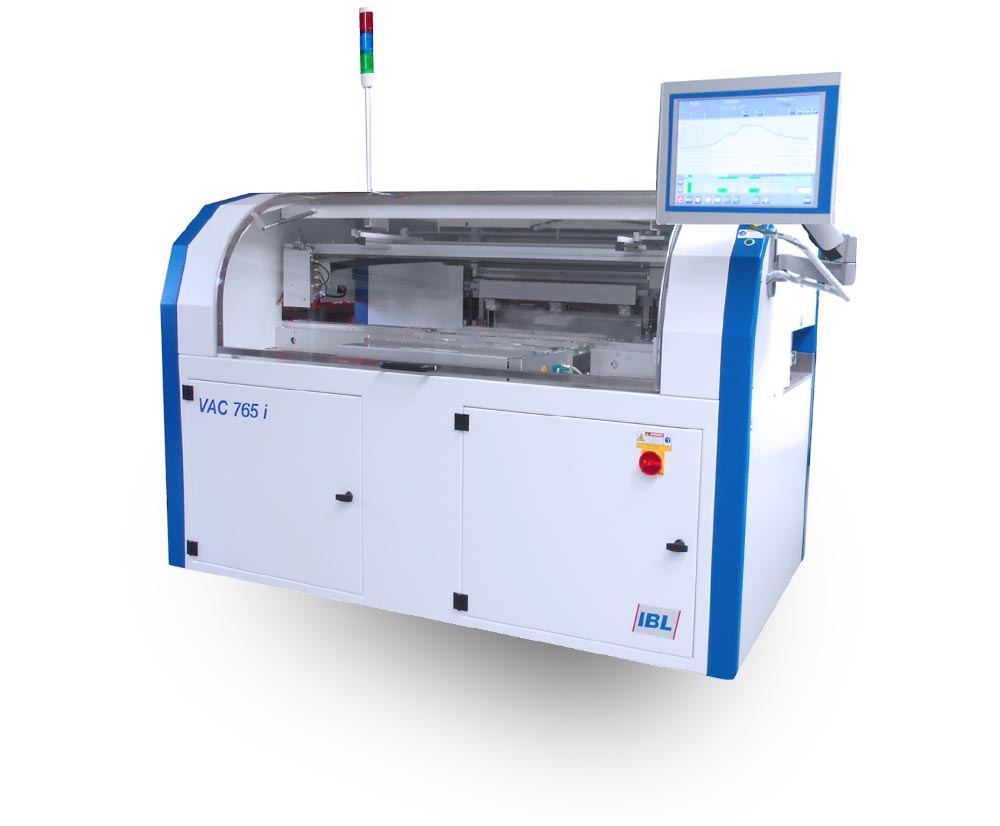

BLC Inline Anlagen  VAC Inline Anlagen

VAC Inline Anlagen  VAC745/765

VAC745/765  Customized Solutions

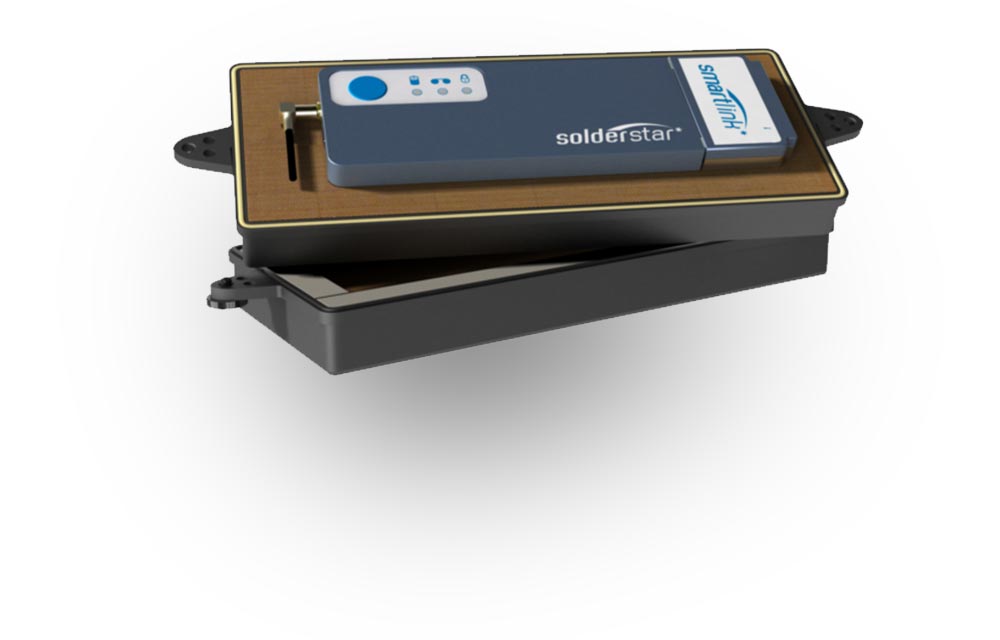

Customized Solutions  Temperature-Profiling

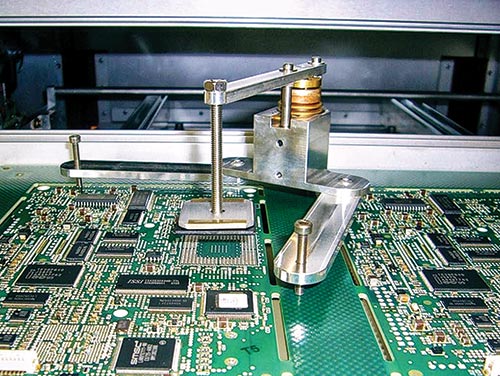

Temperature-Profiling  Rework

Rework  Fluid (Galden®)

Fluid (Galden®)