Vacuum soldering with precision and process reliability

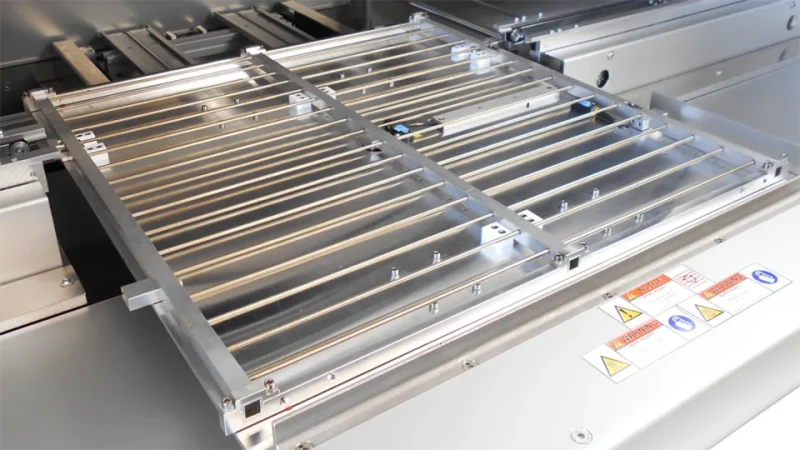

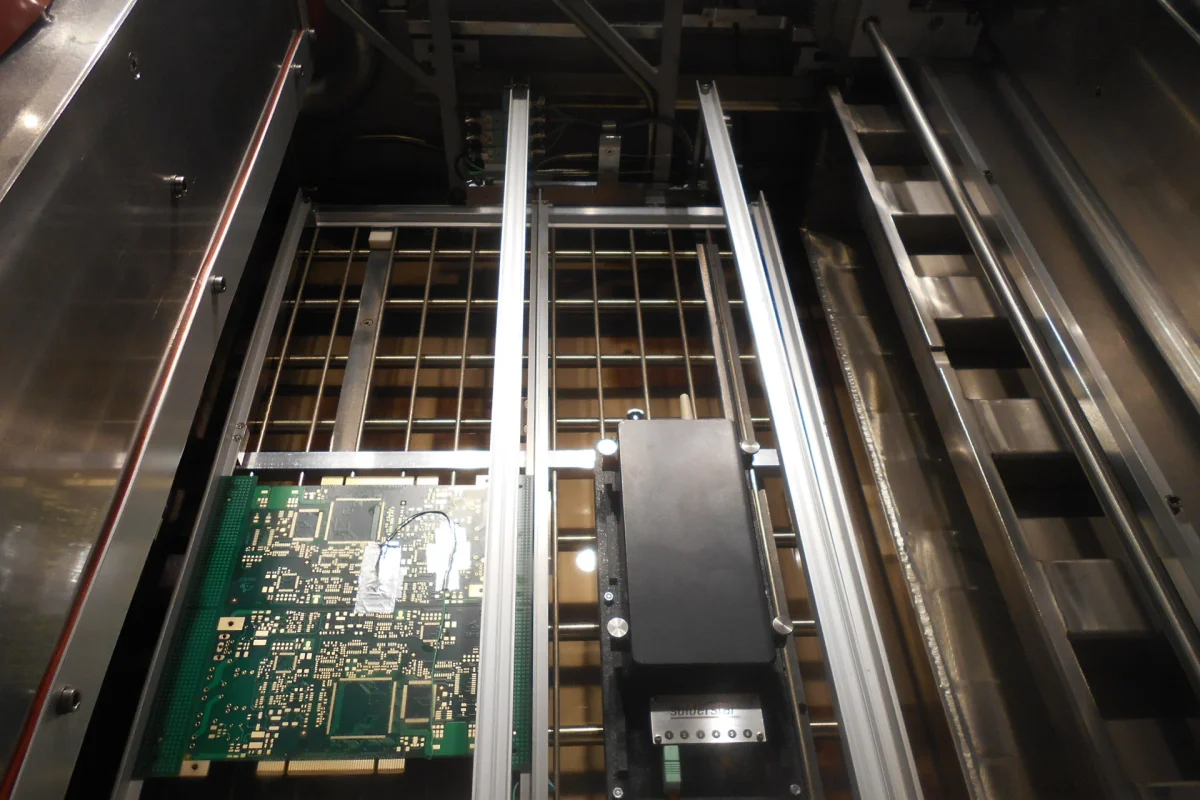

Thanks to the unique system architecture, the VAC745 and VAC765 are particularly suitable for vacuum soldering demanding components such as BGAs, where quality and precision are crucial. The patented technology of these machines ensures outstanding results in terms of performance and quality. The system copes with:

- most complex assembly structures

- regardless of the number of layers in the circuit board

- even with a high component mix

The machine concept is therefore particularly suitable for automated vacuum soldering in series production.

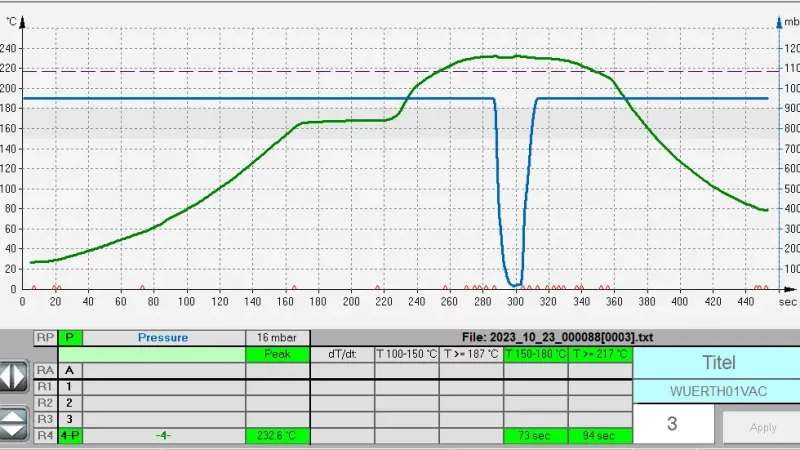

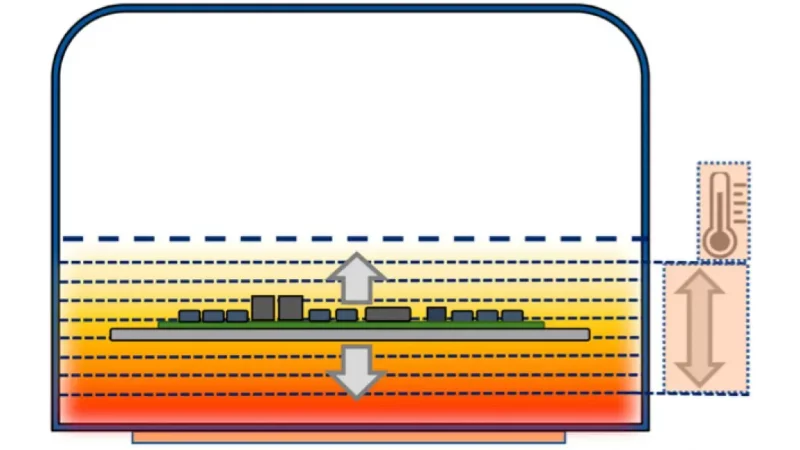

In combination with the patented "Soft Vapour Phase" will:

- reliably prevents an excessive temperature increase of the components

- material stress significantly reduced

- and thus sustainably increases the reliability of the soldering process.

The system guarantees consistent soldering results regardless of the weight of the assembly.

Compared to other vacuum reflow ovens, the VAC series is impressive:

- exceptionally low energy consumption

- lower operating costs

- excellent heat transfer in an inert, oxygen-free atmosphere, without the use of expensive nitrogen.

- two-chamber system with large touch display enables

- intuitive and user-friendly vacuum soldering.

This ensures efficient vacuum soldering at the highest level.