Three variants - maximum flexibility with minimum space requirements

The customer can choose between three machine types with different carrier sizes. Both variants:

- work with a integrated vacuum system

- are for inline and batch operation designed

- only need small footprint

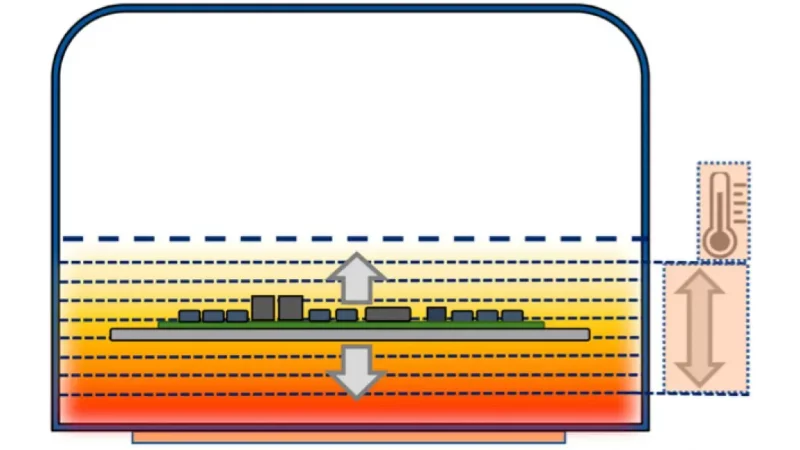

Thanks to the unique vapour phase technology, the machines in the VAC Inline series guarantee excellent soldering results with high reproducibility. Circuit boards with different numbers of layers and an extensive mix of components can be reliably soldered with the vacuum soldering systems. Thanks to the "Intelligent Profiling System", the user has full control over the temperature rise. This allows outstanding soldering profiles to be achieved with pinpoint accuracy.

Further advantages:

- excellent heat transfer in a inert, oxygen-free atmosphere

- no need for expensive nitrogen

- user-friendly two-chamber system with large touch display

- identical profile for all assembly weights usable

The systems in the VAC Inline series are available in three different configurations. All systems are designed for inline vapour phase soldering under vacuum. The customer can choose between three models depending on the workload. Compared to the VAC745i and VAC765i, the machine model VAC745HDxi works simultaneously with 2 workpiece carriers, which increases the throughput by up to 70 % compared to the VAC745i and VAC765i.

In addition, the soldering:

- independent of weight possible with the same profile in one system

- both for lead-free as well as lead-containing processes suitable with only one medium