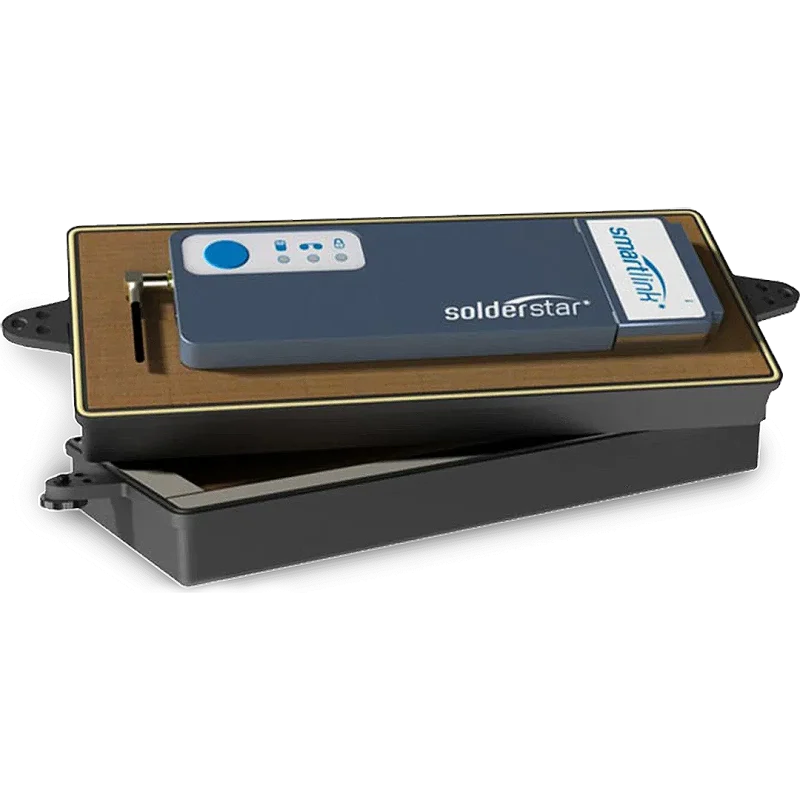

Precise temperature monitoring with Solderstar system

For a particularly precise temperature management in the vacuum chamber, IBL recommends an external profile recording device from Solderstar. This system enables targeted and precise temperature monitoring during soldering directly on the printed circuit boards during the vacuum process.

Integration takes place via the interface between the Solderstar Wireless Profiling System and the IBL VP-Control Software. This means that the data collected by both systems is merged directly in the interface of the IBL system.