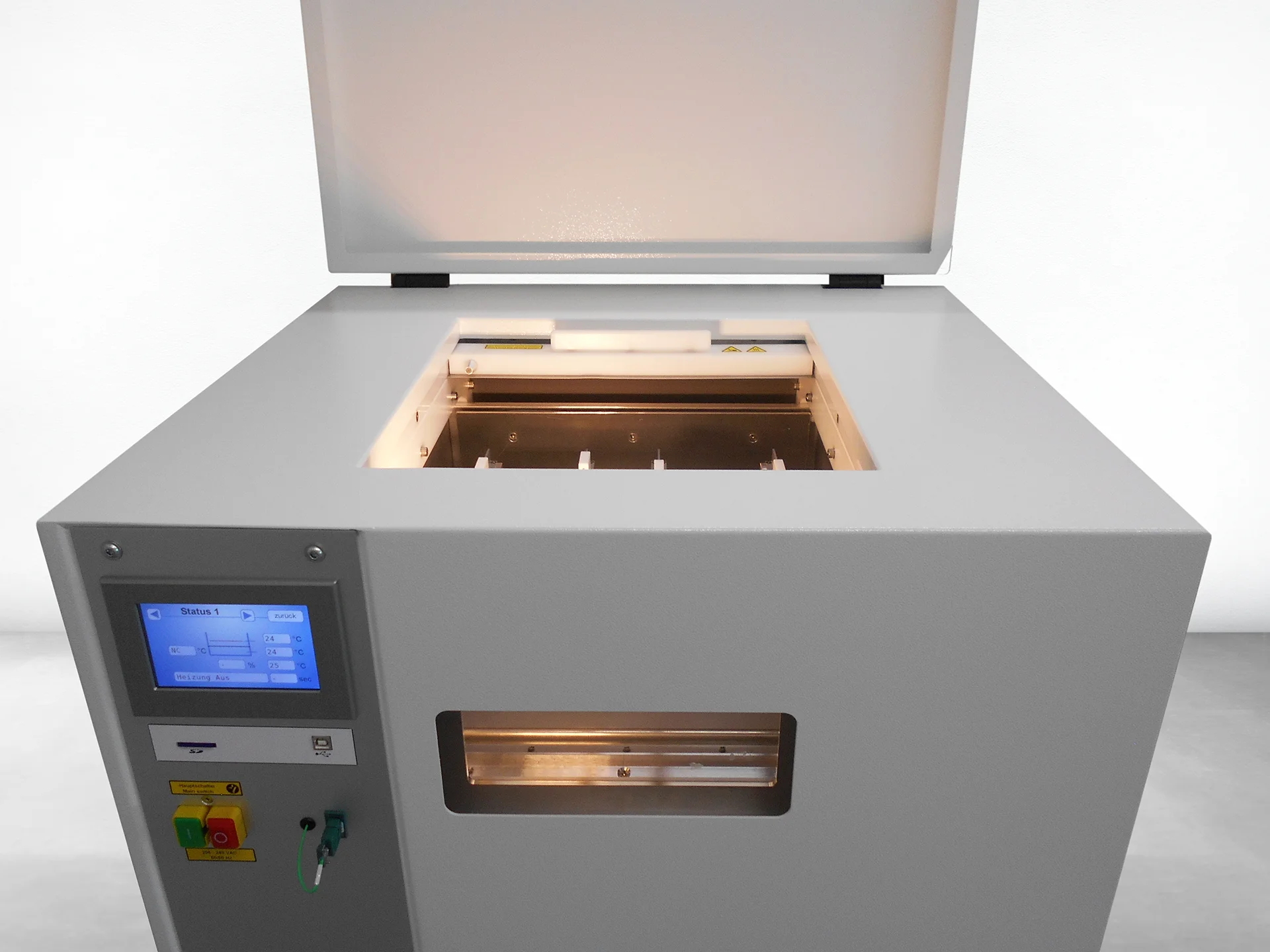

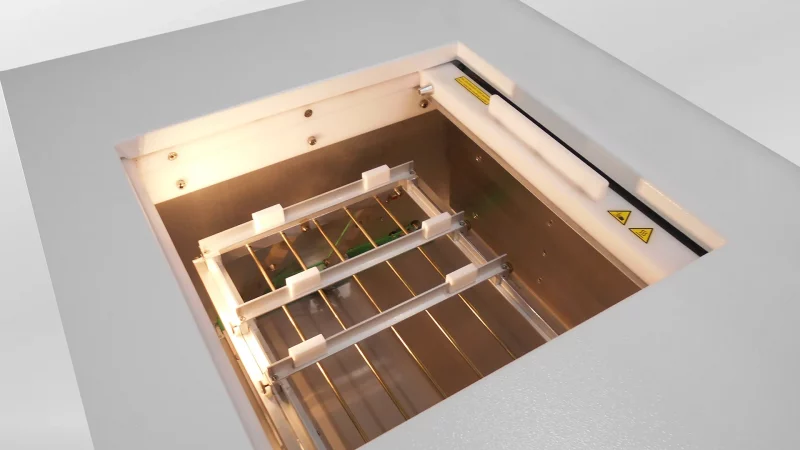

The MiniLab vapour phase machine impresses with its space-saving design and simple operation. The machine is designed for small batch production and guarantees the highest soldering quality with gentle temperature control.

The top-loading vapour phase soldering system guarantees a uniform temperature profile and enables soldering without overheating, ideal for sensitive components. Despite its compact size, the MiniLab impresses with its professional performance and reliable process reliability.