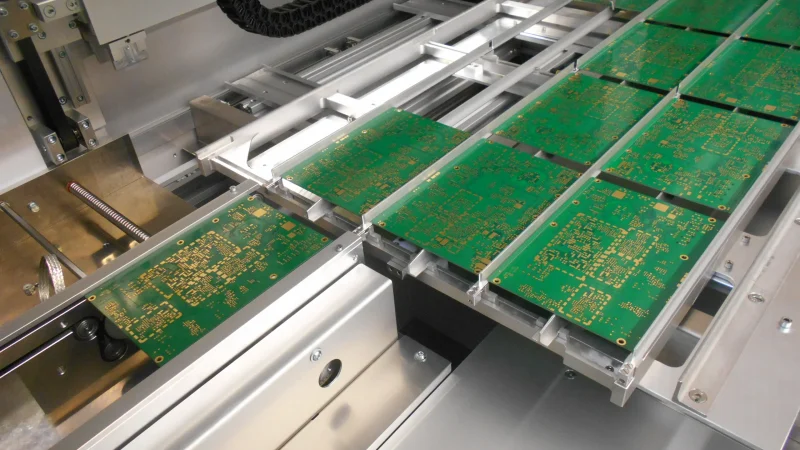

Space-saving, flexible, versatile

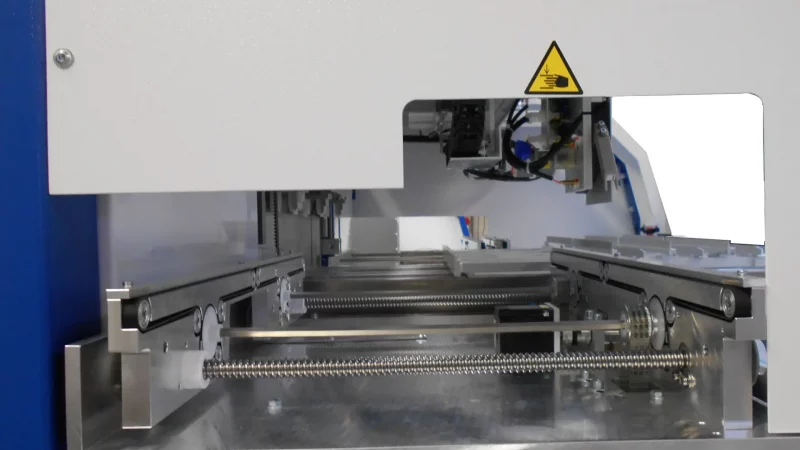

The space-saving BLC inline series is available in different machine types with carrier sizes from 450 x 540 x 80 mm up to 850 x 540 x 80 mm.

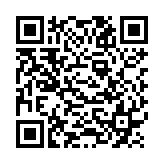

The inline systems can:

- be fully integrated into a production line

- can also be used in batch mode if required

The Intelligent Profiling System (IPS) gives the user full control over the temperature rise and enables a soldering profile to be created in a single step.

Precision through patented technology

Together with the unique, patented Soft Vapour Phase, overheating of the components is ruled out. The BLC inline series has excellent heat transfer in an inert, oxygen-free atmosphere, without the use of expensive nitrogen.

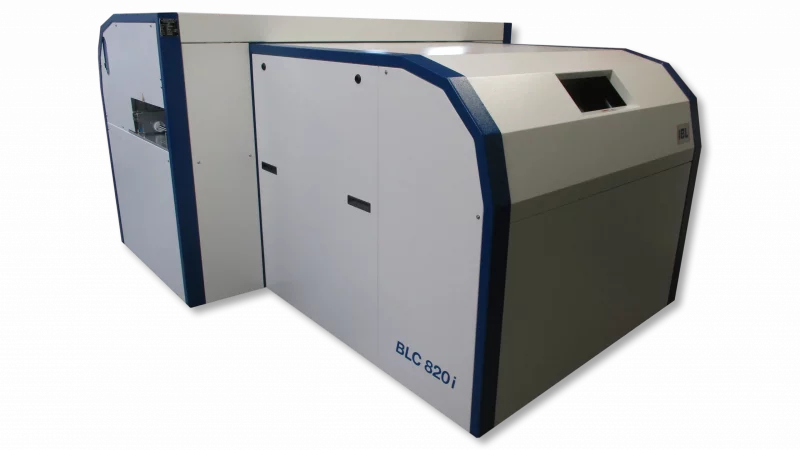

The two-chamber system with large touch display makes this machine particularly user-friendly, as it:

- is easy to set up

- remains easy to use

- delivers reliable results

The Intelligent Profiling System (IPS) enables easy and intuitive control of the thermal profile in the high-end range.

Low consumption figures lead to lower operating costs

The two-chamber design and integrated heat exchanger reduce energy consumption.

This is lower with the BLC inline series compared to other soldering systems, which saves operating costs.

Media consumption is also low, thanks to:

- integrated medium recovery

- minimum fluid consumption

Both factors contribute to overall cost- and resource-efficient production.