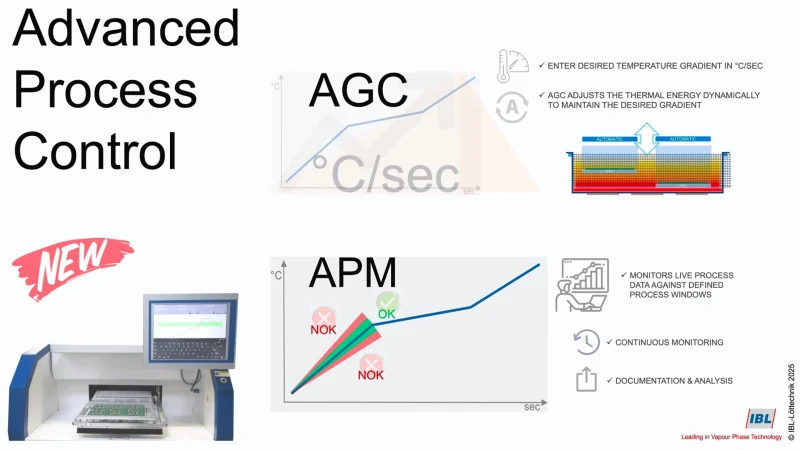

Your advantages at a glance:

- intuitive operation: temperature settings without complex calculations

- maximum process reliability: Precise profile control for perfect solder joints

- increased efficiency: faster set-up, fewer rejects, optimum quality from the first run

- flexibility: gradients can be adapted precisely to individual requirements

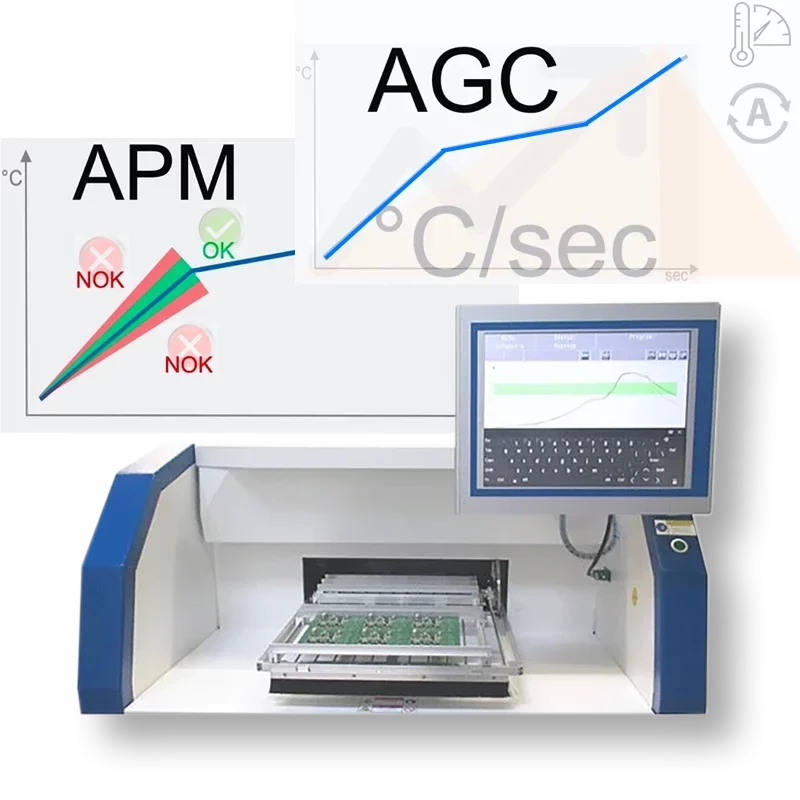

Seamless monitoring with Advanced Process Monitoring

In combination with the Advanced Process Monitoring (APM) function, users receive 24/7 process monitoring of all relevant parameters in IBL vapour phase soldering systems. The precise recording, analysis and documentation guarantees the highest soldering quality, complete traceability and enables the early detection and avoidance of production errors.

Industries such as automotive, aerospace and medical technology in particular benefit from this seamless monitoring. It meets the requirements for certification in accordance with common standards (e.g. IPC, ISO) and ensures that every production run is carried out under identical conditions. Deviations in preheating time, soldering time or vacuum pressure are detected immediately so that corrective measures can be initiated and series errors avoided.

With Advanced Process Control and Advanced Process Monitoring, IBL offers a powerful combination of intuitive operation, maximum process reliability and complete traceability, thus creating the basis for maximum quality and productivity in electronics production.