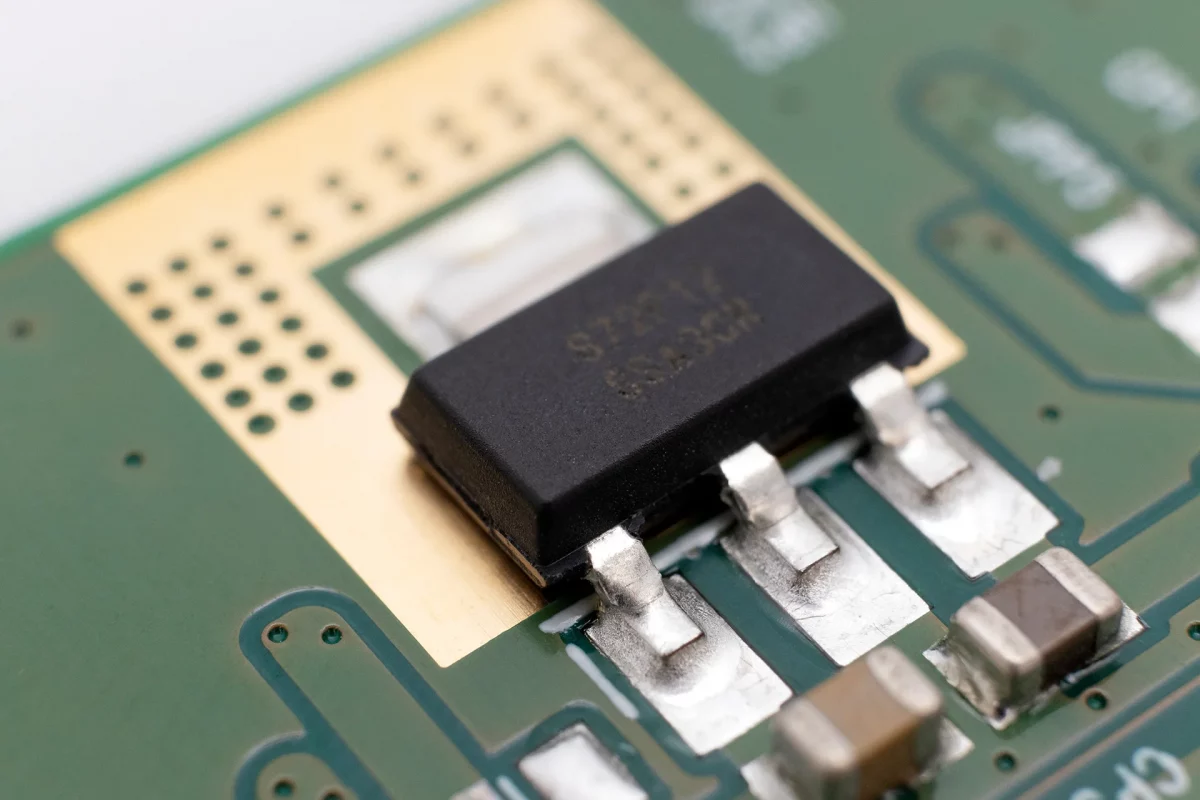

All soldering processes have one thing in common: they are able to securely attach components to special substrates. However, for greater process accuracy, higher quality solder joints, uniformly repeatable heating and lower reflow costs, vapour phase soldering (also known as condensation soldering or vapour phase reflow) offers the most flexible, simple and reliable reflow soldering process.

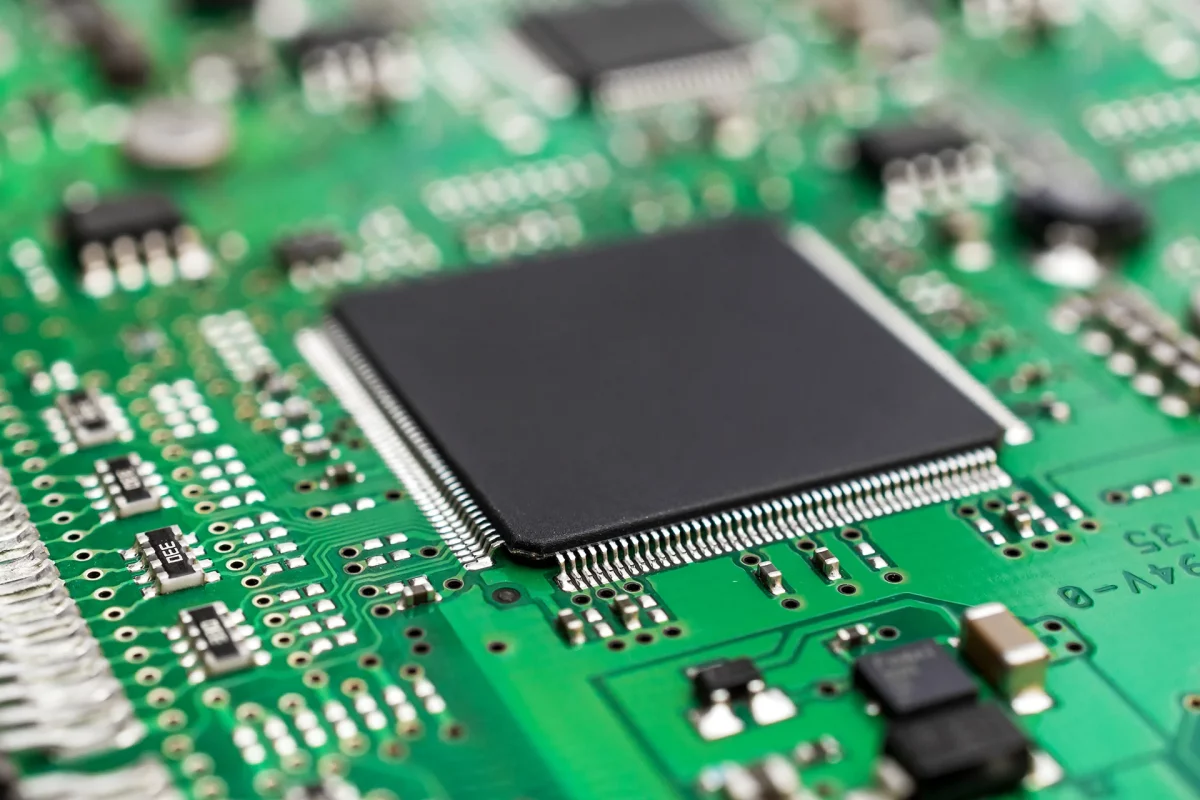

These vapour phase soldering technology is ideally suited for all types of SMT components and carrier materials. It enables the processing of the complete component spectrum without complex installation and without temperature profiling and is therefore ideal for modern electronics production.

Basic configuration

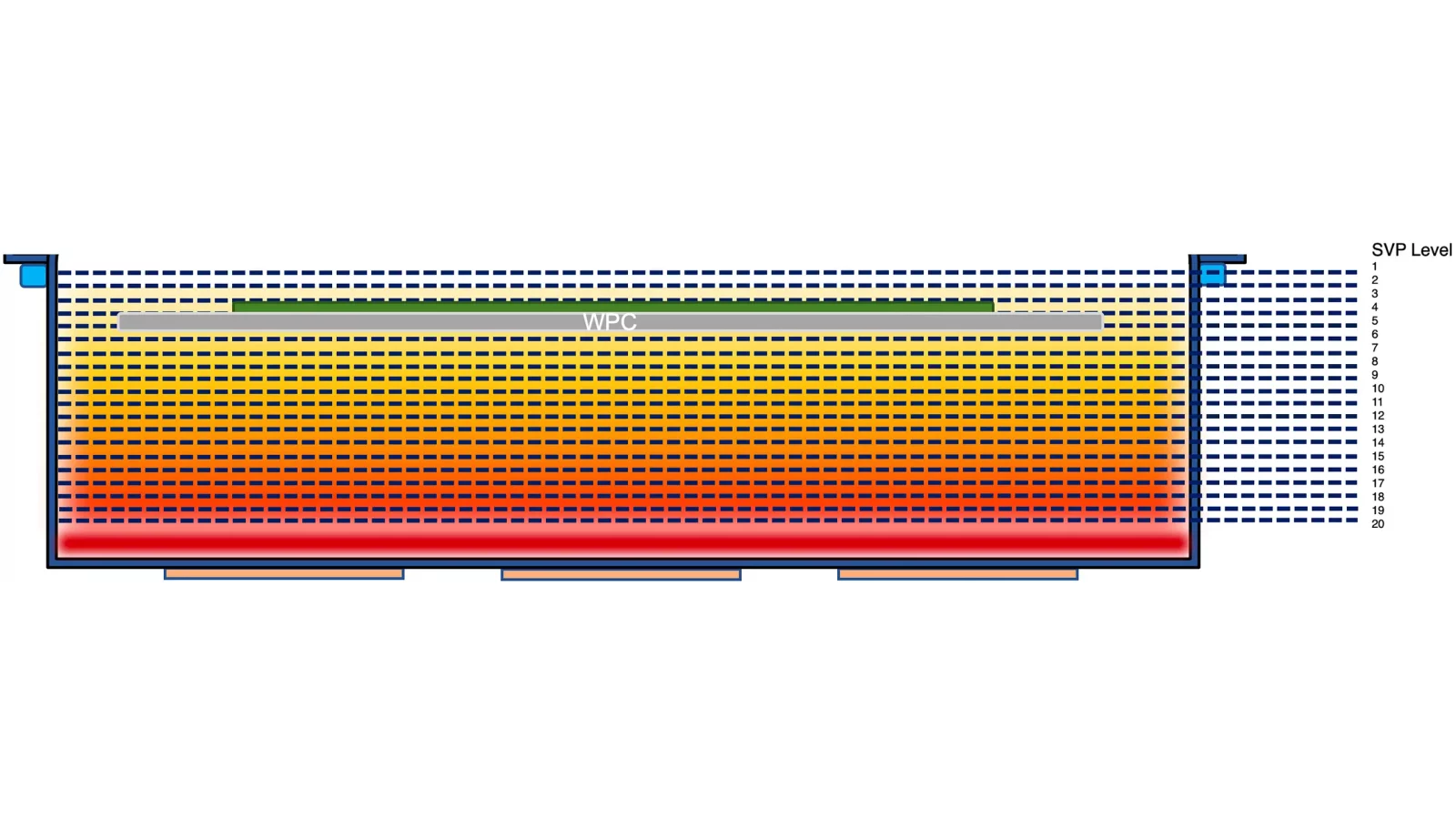

To the heat transfer in the vapour phase a chemically inert and electrically non-conductive liquid is used, typically Galdena medium that is characterized by high thermal stability. This harmless and very stable liquid, which does not combine with other substances, has a boiling point of 165 °C to 260 °C, depending on the application. Other temperatures are possible depending on the Galden-based vapour phase furnace-configuration is also available.

The process

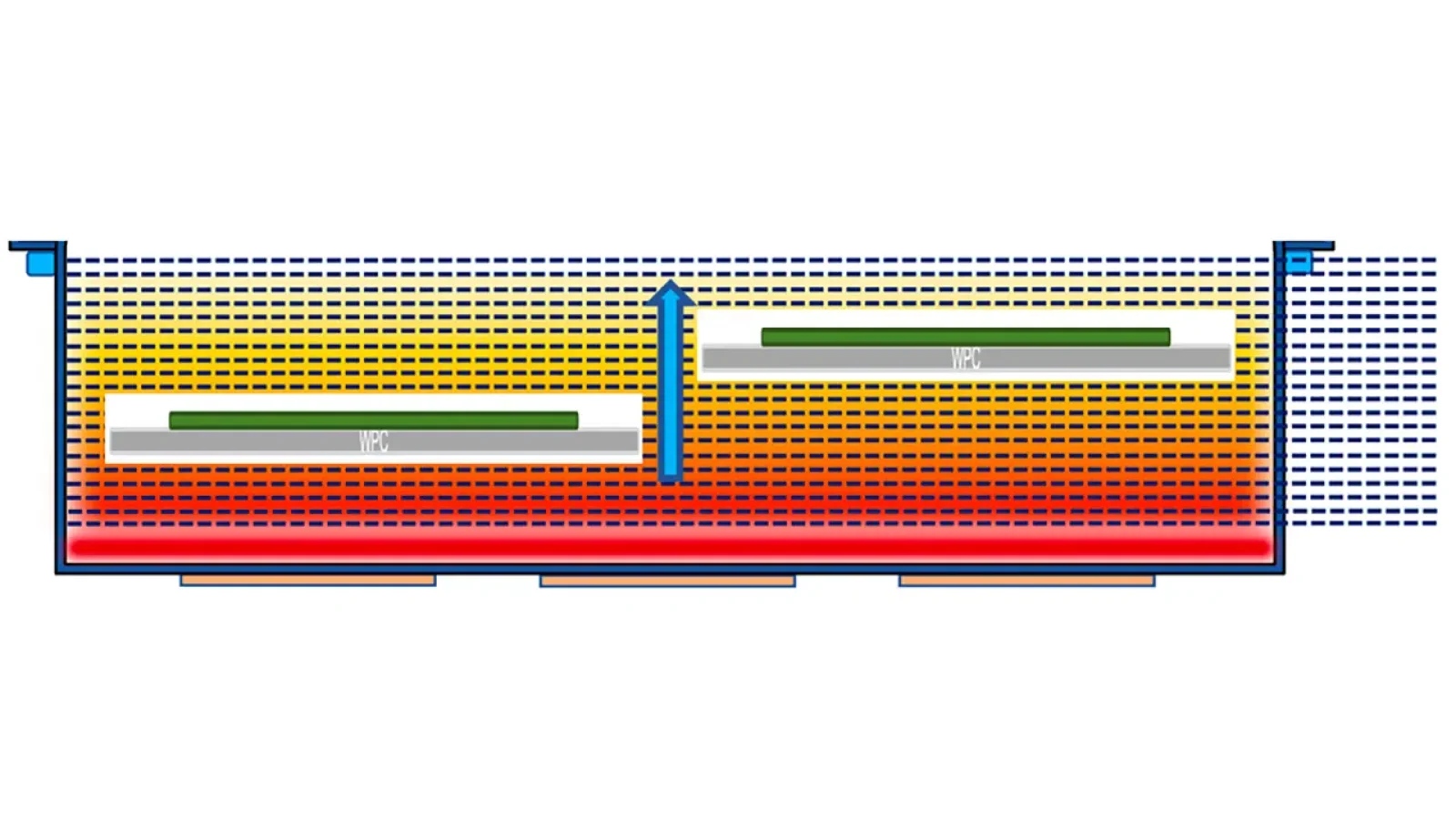

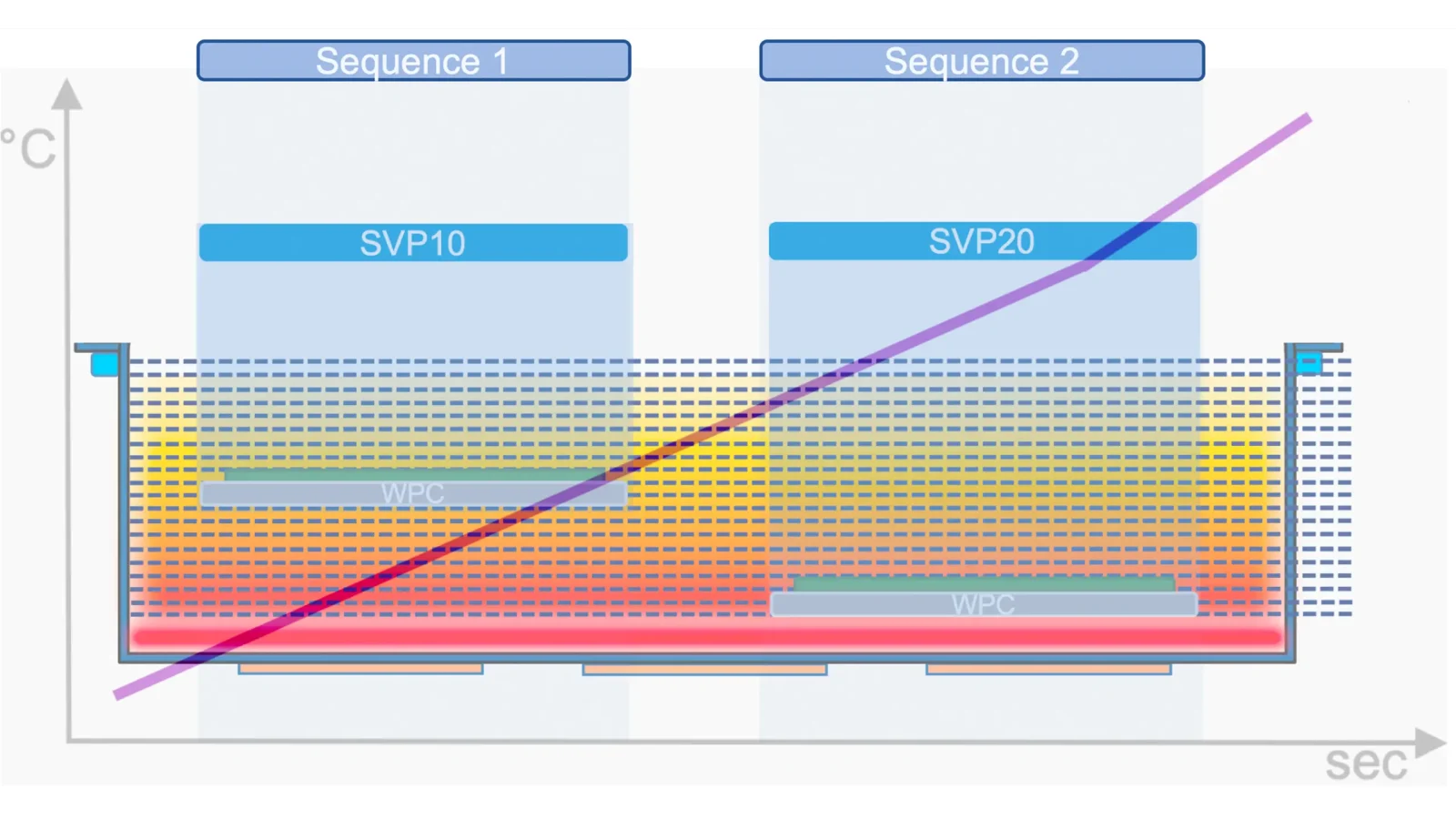

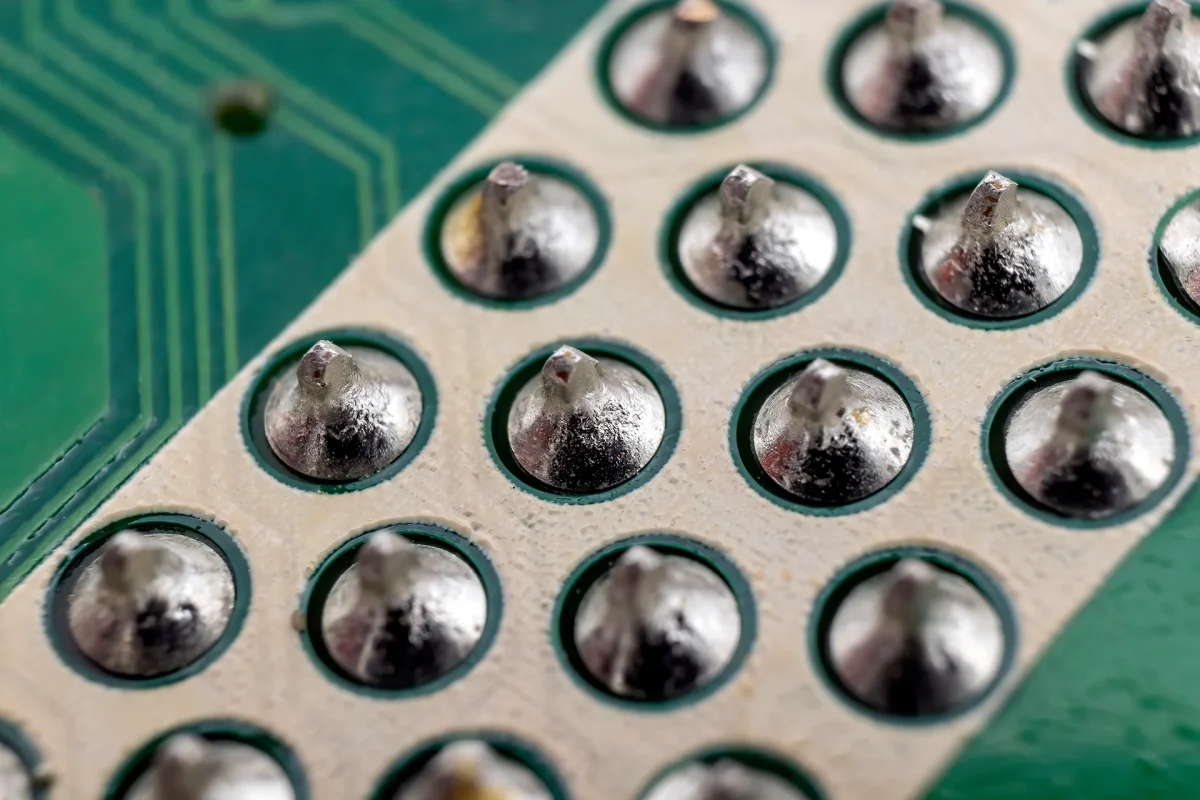

When the liquid boils, a blanket of saturated vapour forms above it, creating an optimum inert gas atmosphere that prevents oxidation in the liquid. Vapour phase soldering process is excluded. This takes place according to the condensation principle. When the assembly is immersed in the vapour zone, the vapour condenses on the soldering material and transfers its thermal energy.

Regardless of how long the soldering material remains in the vapour phase, its temperature can never be higher than that of the vapour. Physical laws determine these framework conditions and make the process particularly gentle on sensitive assemblies.

The result

The vapour phase soldering process is reproducible and offers ideal conditions for reliable and repeatable process monitoring. Modern, high-quality vapour phase soldering systems from IBL enable consistent results and the highest soldering quality, from flexprint to multilayer, without overheating.