Vacuum vapour phase soldering: system for void-free soldering

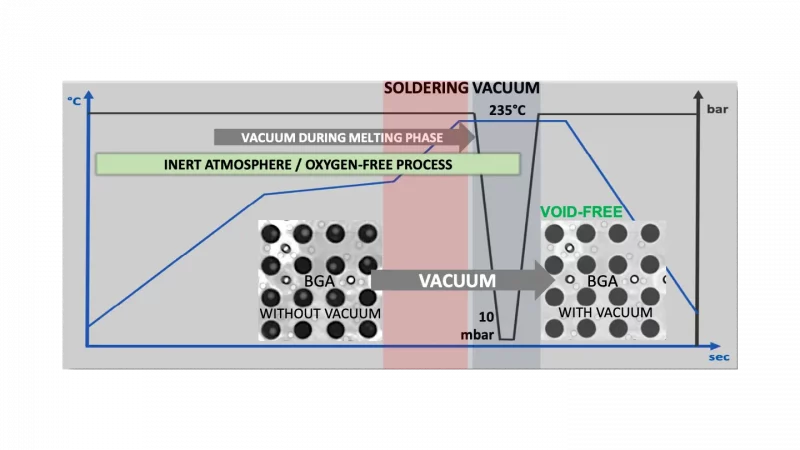

A special form of classic vapour phase soldering is the vacuum vapour phase soldering also known as reflow with vacuum. This process offers a decisive extension for particularly demanding applications.

Once the solder paste has completely melted, the air is removed from the process chamber. The resulting negative pressure ensures that gaseous inclusions are pressed out of the solder joints. This results in particularly homogeneous, void-free joints, a key feature of pressureless soldering.

Efficiency in series production

Vacuum soldering has established itself above all where the highest quality is required, for example in the soldering of BGA components or in power electronics.

In modern production lines, this process is increasingly used as a inline vacuum soldering implemented. This enables:

continuous processes with high throughput

consistent quality without manual intervention

complete integration into automated lines

Advantages of vacuum vapour phase soldering

- blowhole-free solder joints for maximum mechanical stability

- void-free connections which minimize the thermal resistance

- optimum heat dissipation especially for high-performance components

- greater reliability of the solder joint in critical applications

The reduction of air inclusions is particularly crucial for thermally conductive solder joints, as any void formation can impair the soldering process. Thermal conductivity deteriorates and the mechanical load capacity reduced.

Conclusion

Vacuum vapour phase soldering is more than just a supplement to the classic vapour phase process, it is a decisive step towards maximum quality and process reliability in assembly production.