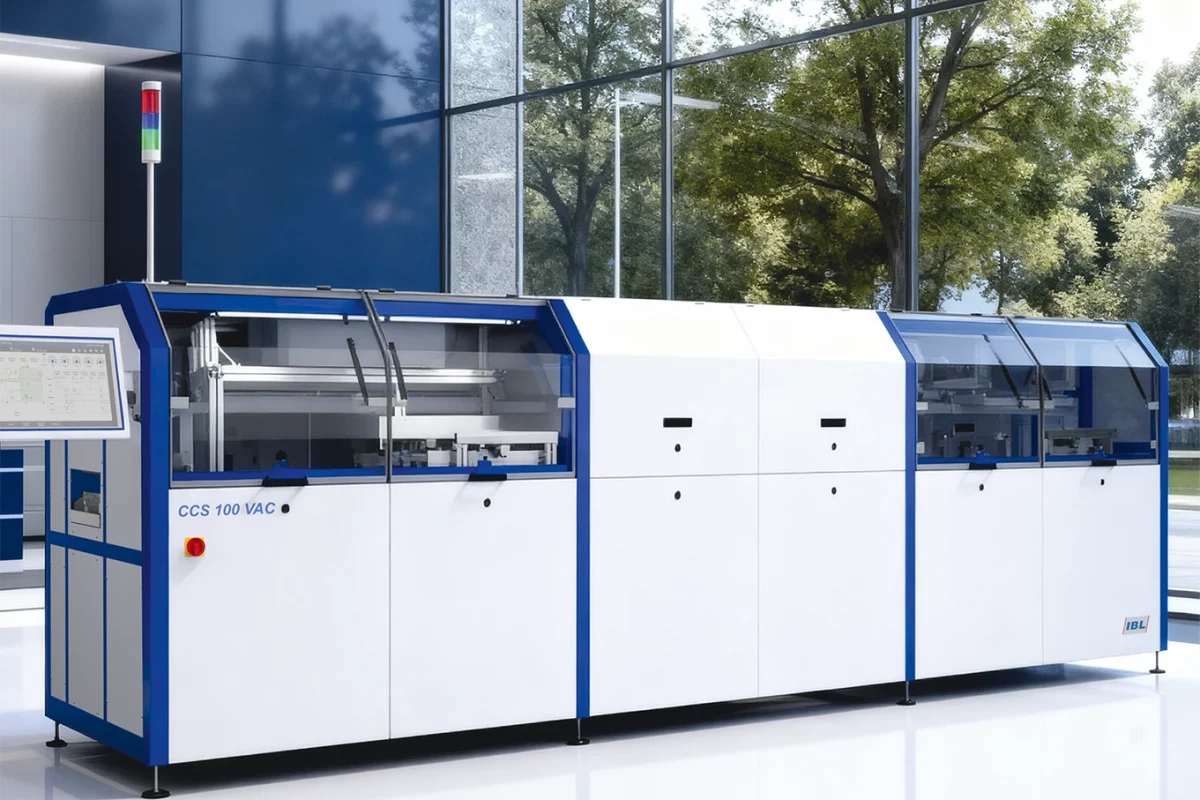

The vapour phase soldering systems from IBL make an important contribution to the implementation of the "Right to Repair" because they enable repair, refurbishment and rework processes on complex electronic assemblies to be carried out gently and reproducibly. Thanks to the principle of the saturated vapour phase, the assembly is only heated up to the defined boiling temperature of the medium, which prevents PCBs or sensitive components from overheating. This uniform and controlled heat transfer reduces thermal stresses and delamination and ensures that components are not damaged during desoldering and soldering. Furthermore, the same temperature profiles can be used in series soldering for soldering a single assembly, so that even complex profile adjustments by the operator are not necessary.

IBL offers the ReSy for desoldering complex components. This is a fast and cost-effective tool for reworking components such as BGAs and QFBs. The ReSy system uses a patented, temperature-dependent lifting device that removes components gently and without force after desoldering. This leaves the assembly intact.

Furthermore, temperature profiles can be precisely set, documented and repeated in the vapour phase, allowing repairs to be safely carried out and verified in accordance with current standards. Thanks to these properties, IBL systems can also be configured for individual PCBs or small batches, making them ideal for integration into rework and refurbishment lines. In this way, vapour phase technology not only supports manufacturers and service providers with rework or repairs, but also actively contributes to the extension of product life cycles, the reuse of valuable components and the reduction of electronic waste. These are key objectives of the "Right to Repair".