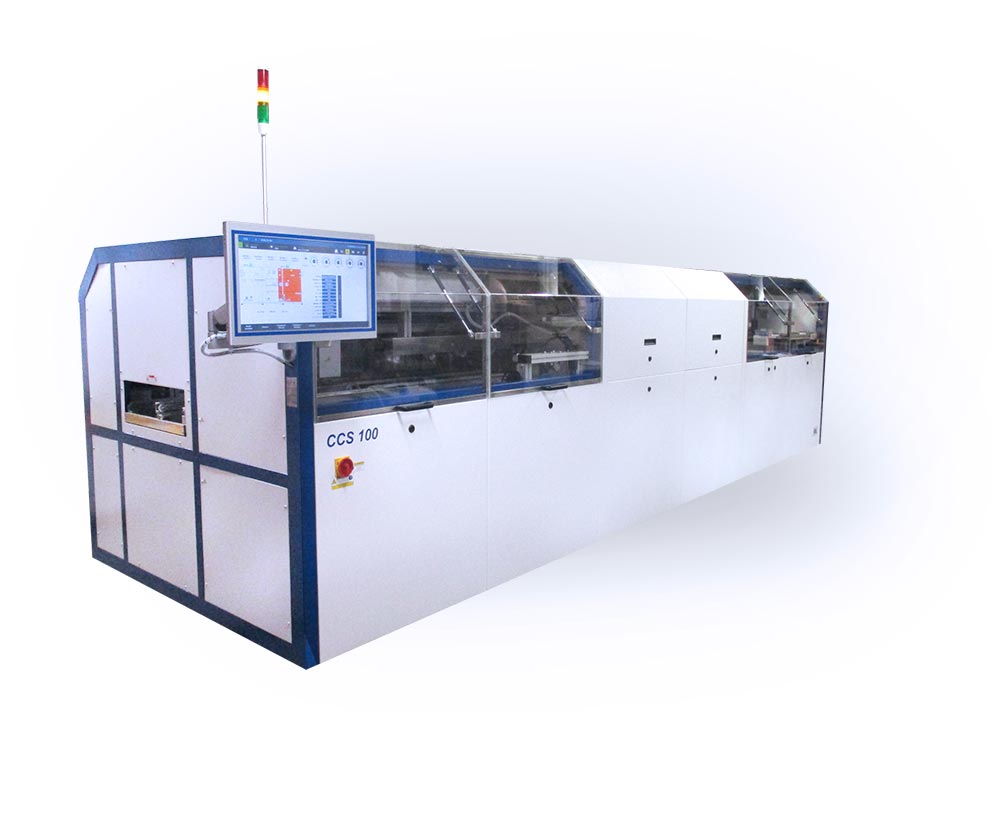

CCS100

The CCS100 is a compact high-performance inline system which was designed for the 24/7-operation. The line capable system convinces by its high process flexibility, extraordinary high productivity and solder quality.

With the applied multiple-carrier system the machine is meeting the requirements of mid- to high-series productions, further new developed systems as well as the modular structure are lowering the maintenance efforts und lead to a very high machine availability.

The modern machine control allows precise process control as well as anytime visible process values and steps. The data management takes place by an integrated industrial PC and the visualization is realized by a 21,5”-HMI panel. This means that the CCS100 can easily be connected to customer ́s side networks offering wide possibilities and features for Traceability and process data collection. Furthermore, a new benchmark in the field of process technologies for vapour phase soldering systems was set with the newly developed, patented Vapour Energy Control (VEC). As a result, the machine realises a very flexible and responsive control system with which any type of profile can be set and repeated – withoutthe movement of the PCBs in the vapour.

Features

- Multiple-carrier system with variabel lane configuration of the work piece carriers

- Work piece carrier return transport

- Modular design, multi-zone construction with upstream buffer and downstream cooling zone

- Powerful bottom cooling for board cooling after the soldering process

- Efficient Maintenance System with Galden levelling and filtering system

- Maintenance-friendly design

- Heat exchanger systems for efficient fluid recovery

- Automatic lane width adjustment of the conveyor systems

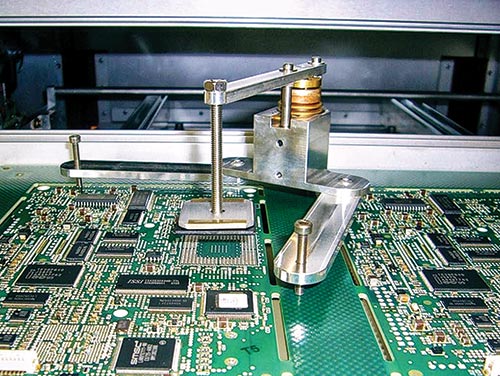

- Automatic loading and unloading of the boards

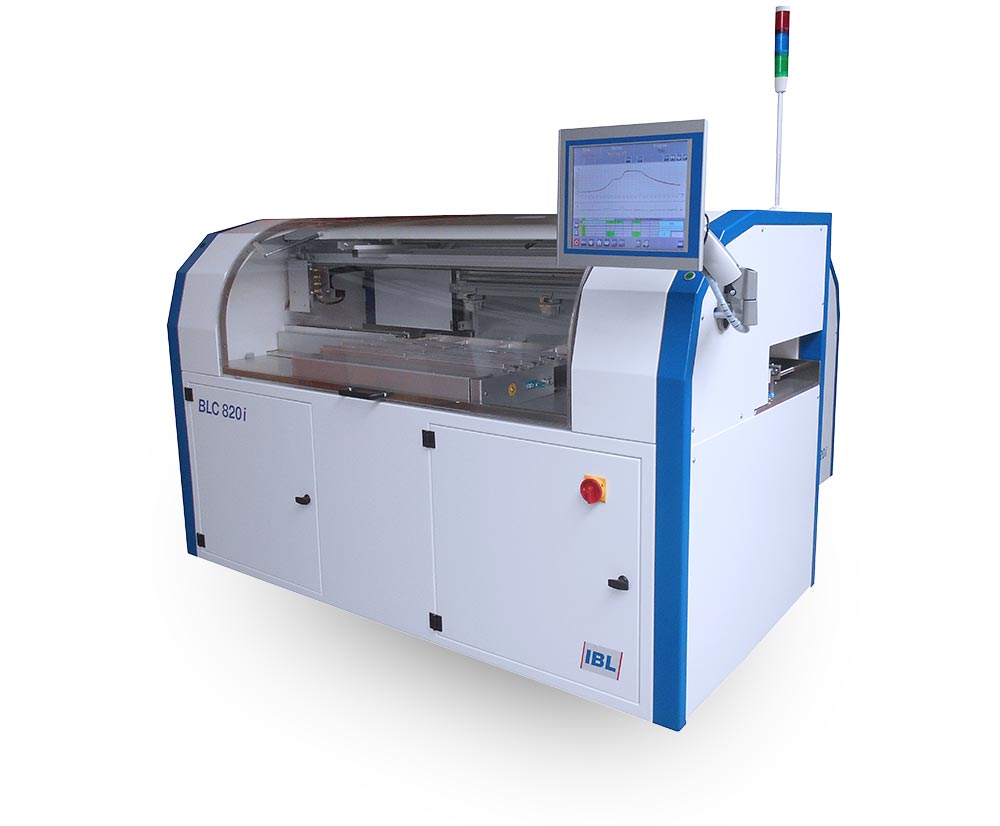

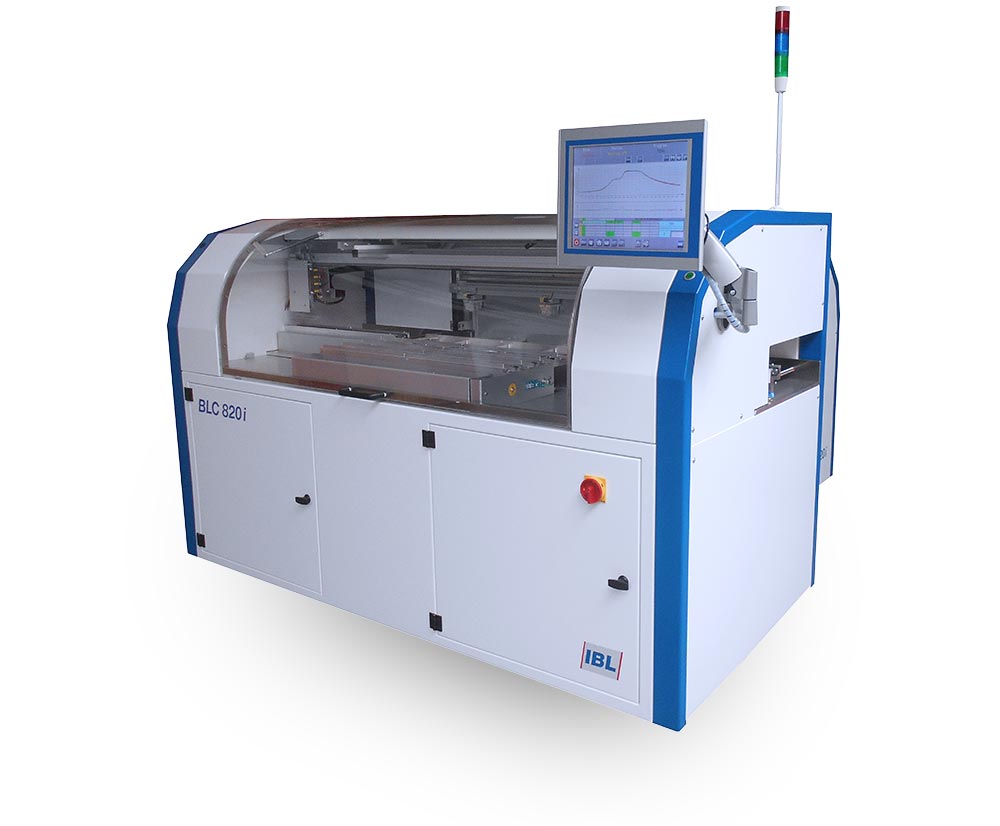

BLC Inline

Features

- Powerful unit for highest demands

- Different machine types with carrier sizes from 450 x 540 x 80 mm up to 850 x 540 x 80 mm

- Small footprint

- Low energy and fluid consumption with 2-chamber design and integrated heat exchanger

- Highest precision and process quality with patented Soft Vapor Temperature Control (SVTC)

- Easy one step profile set-up with Intelligent profiling system (IPS)

- Wide variety of adjustable solder profiles

- Lead-free and leaded soldering on one machine with one fluid

- Live temperature monitoring with IBL Software (VP-Control) without profiler

- Traceability and documentation with IBL Software (VP-Control) optionally with barcode function

- Low maintenance due to Cool Handling (all moving parts outside process chamber)

- Maintenance-free transport system (patented)

- Integrated automatic fluid filter system

- Observation window into process chamber

- Optional patented Rapid Cooling System (RCS) for heat reduction of sensitive parts

Different sizes are available on request

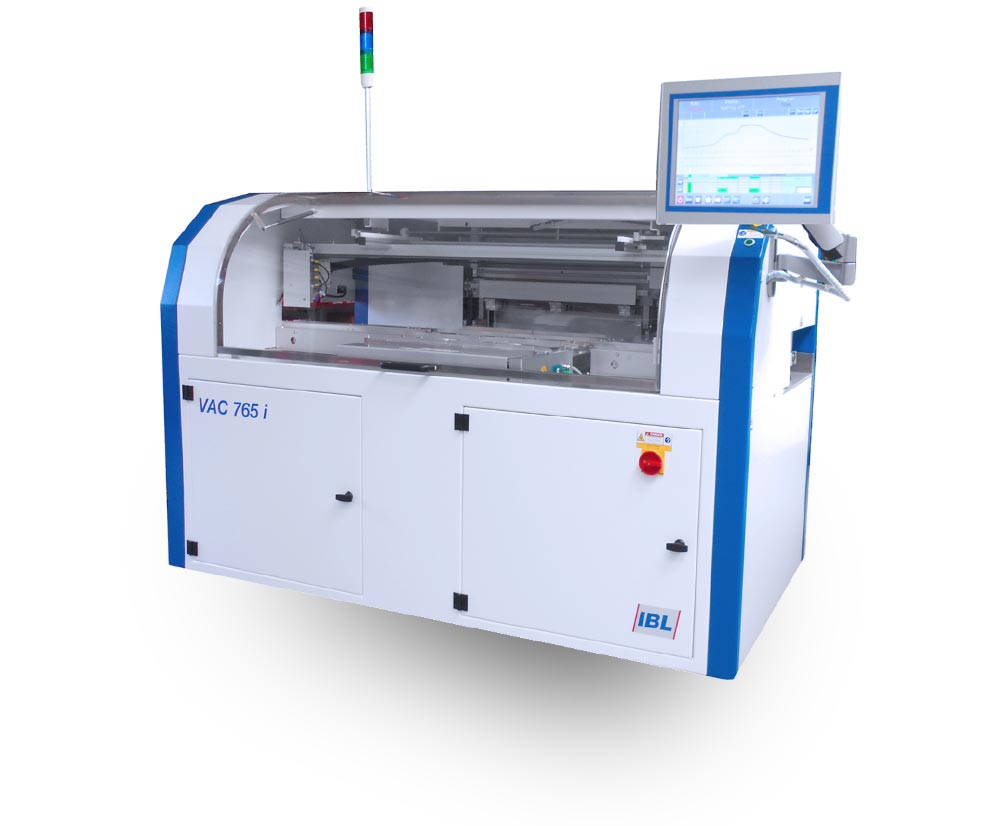

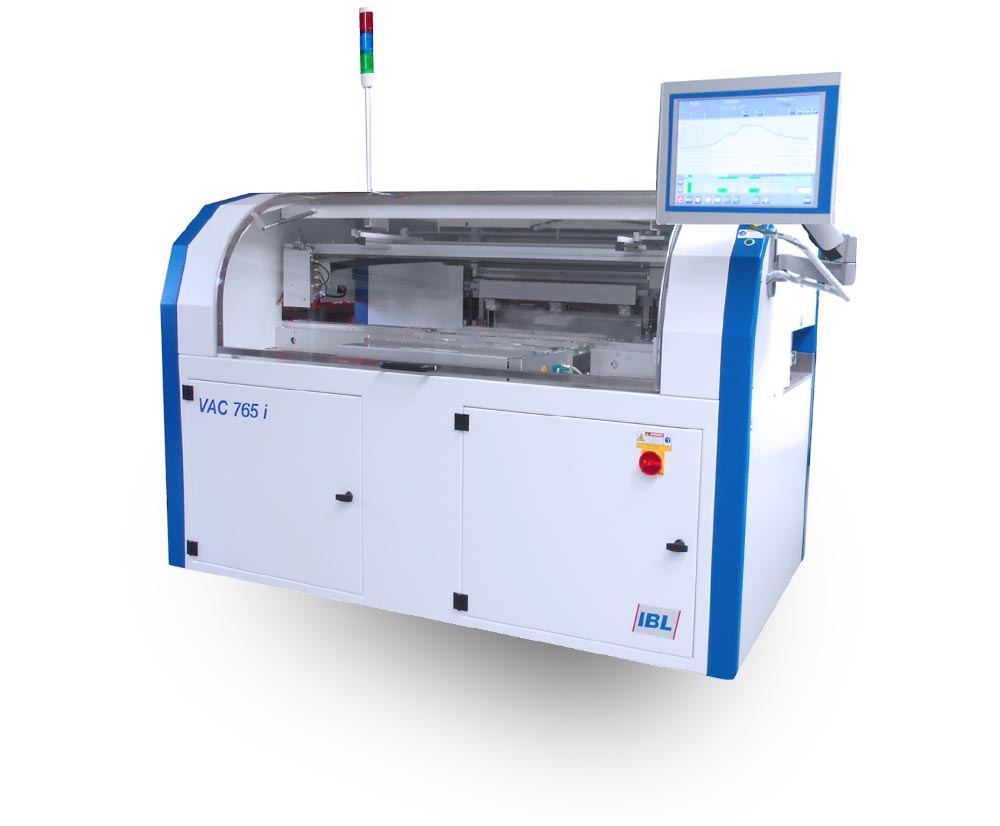

VAC Inline

Features

- Powerful unit for highest demands

- Different machine types with carrier sizes

- Small footprint

- Low energy and fluid consumption with 2-chamber design and integrated heat exchanger

- Highest precision and process quality with patented Soft Vapor Temperature Control (SVTC)

- Easy one step profile set-up with Intelligent profiling system (IPS)

- Wide variety of adjustable solder profiles

- Lead-free and leaded soldering on one machine with one fluid

- Live temperature monitoring with IBL Software (VP- Control) without profiler

- Traceability and documentation with IBL Software (VP-Control) optionally with barcode function

- Low maintenance due to Cool Handling (all moving parts outside process chamber)

- Maintenance-free transport system (patented)

- Integrated automatic fluid filter system

- Observation window into process chamber

- Optional patented Rapid Cooling System (RCS) for heat reduction of sensitive parts

Different sizes are available on request

Minilab

Minilab  SV260 Economy

SV260 Economy  SV540 Economy

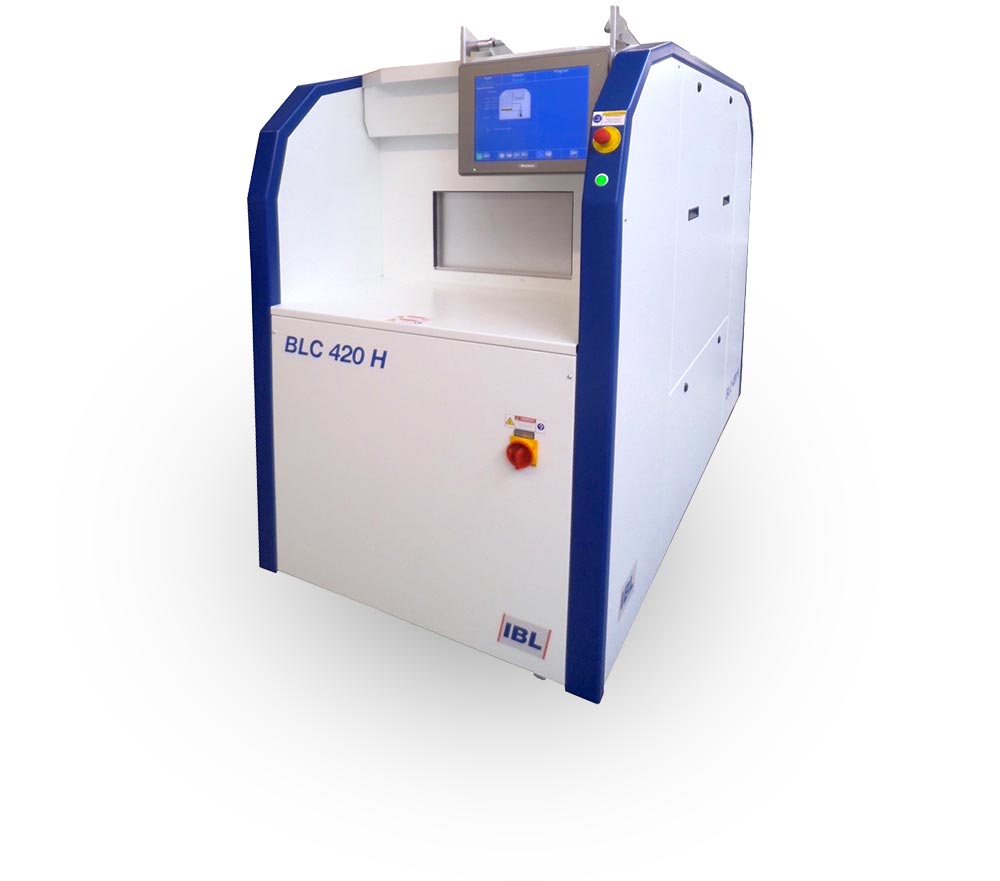

SV540 Economy  BLC-Serie

BLC-Serie  CCS100

CCS100  BLC Inline Anlagen

BLC Inline Anlagen  VAC Inline Anlagen

VAC Inline Anlagen  VAC745/765

VAC745/765  Customized Solutions

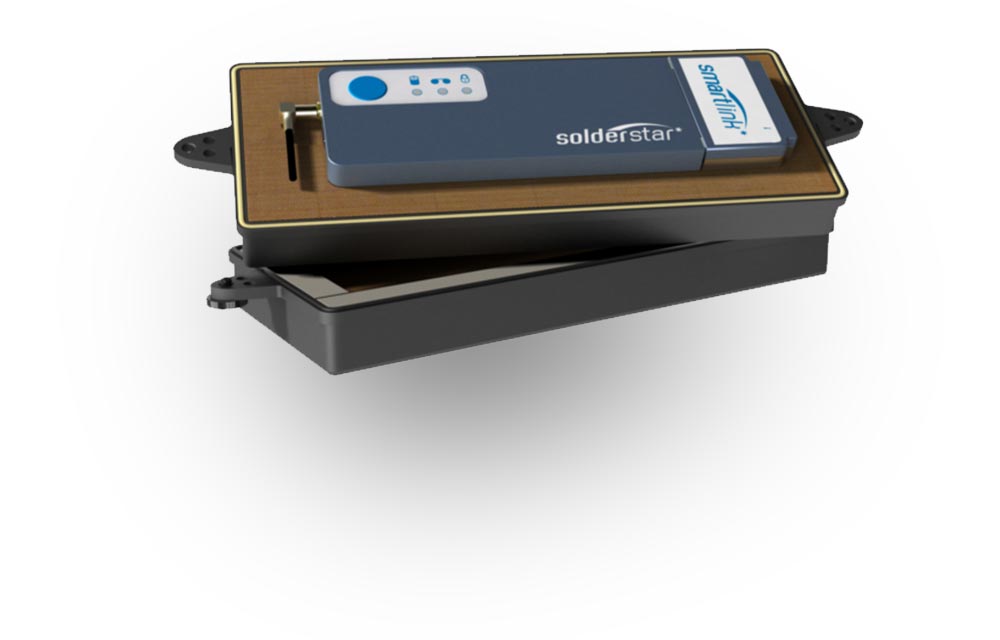

Customized Solutions  Temperature-Profiling

Temperature-Profiling  Rework

Rework  Fluid (Galden®)

Fluid (Galden®)